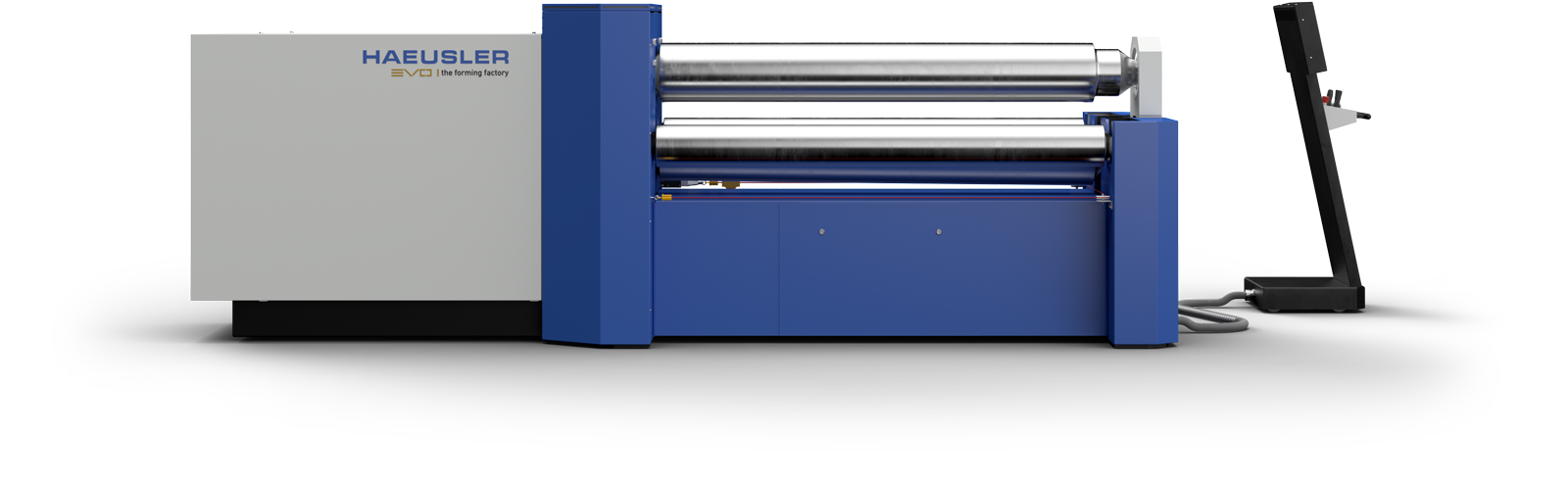

EVO 4-roll plate bending machine│Bending becomes child’s play

THE BENDING

EVOLUTION

EVO 4-roll plate bending machine │Bending becomes child’s play

Better than anything,

what you know…

Low operating costs, increased productivity and easy to use: The Haeusler EVO has a whole load of remarkable advantages in its luggage. Of course in proven HAEUSLER quality – made in Germany.

Advantages

at a glance

Reduction of maintenance costs

Maximization of the plate bending range

Modern and functional design

Bending becomes child's play

Avoidance of downtimes

EVO 4-roll plate bending machine │Machines in Real-Life Operation

More power, more control,

more evolution

AUTONOMOUS BENDING

With the help of the system’s intelligent information feedback, a fully automatic bending process is possible from the first sheet with little rework and no rejects.

DISCOVER MORE

High Productivity

with most simple operation

THE EVO is packed with innovative and patented features that increase your production capacity and productivity while offering the lowest total cost of ownership. In addition to the high-quality components used in this machine, a special highlight is the latest version of the BENDtronic control system, which is installed as standard on all EVO machines. This patented control system is the only one that uses artificial intelligence to optimize your bending result from the very beginning. At the same time it is absolutely intuitive and easy to operate.

Reduction of maintenance costs

The Haeusler Hybrid Drive System HHDS reduces maintenance costs by up to 50% and allows a 60% increase in rotation speed compared to other round bending machines.

Maximising the sheet bending range

With the newly developed and patent-pending VSA technology, a performance increase of up to 85% can be realised.

Modern and functional design

Modern appearance, high protective function and at the same time optimal operability. These criteria were decisive in the development of the machine.

Bending becomes child's play

The latest generation of HAEUSLER's patented BENDtronic 2.0 control with integrated artificial intelligence enables the operator to achieve perfect bending results right from the start.

Avoidance of downtime

The use of optionally available special sensors enables predictive maintenance of the machine. This can reduce unplanned downtime.

HHDS –

HAEUSLER Hybrid Drive System HHDS®

THE EVO is packed with innovative and patented features that increase your production capacity and productivity while offering the lowest total cost of ownership. In addition to the high-quality components used in this machine, a special highlight is the latest version of the BENDtronic control system, which is installed as standard on all EVO machines. This patented control system is the only one that uses artificial intelligence to optimize your bending result from the very beginning. At the same time it is absolutely intuitive and easy to operate.

The two graphs shown above illustrate the two major advantages of HAEUSLER‘s HYBRID-DRIVESYSTEM. 60% faster speed, which is particularly interesting for bending and calibrating large diameter shells, as well as the huge savings potential in maintenance costs that can be achieved by using the HAEUSLER HYBRID DRIVE SYSTEM.

VSA TECHNOLOGY

ALLOWS BENDING OF THICKER PLATES AND SMALLER DIAMETERS

The new and patent pending VSA® – technology allows the operator to bend either very heavy wall thicknesses or alternatively very small diameters. This can be realized by a unique adjustment of the bending geometry. The EVO is worldwide the only 4-roll plate bender with this unique feature. For our clients it means that they are now in a position to get a machine with up to 85% more bending moment compared to conventional bending machines. Additionally they get the possibility to use super small interchangeable top rolls for bending tight diameters.

MACHINE RANGE

The following sizes are available as standard with short delivery time.

| 15 Series | EVO 21015 | EVO 26015 | EVO 31015 |

|---|---|---|---|

| Rolls width (mminches) | 210082 | 2600102 | 3100122 |

| Rounding capacity (mminches) | 125/8 | 111/2 | 103/8 |

| Pre-bending capacity (mminches) | 93/8 | 93/8 | 85/16 |

| 31 Series | EVO 21031 | EVO 26031 | EVO 31031 |

|---|---|---|---|

| Rolls width (mminches) | 210082 | 2600102 | 3100122 |

| Rounding capacity (mminches) | 173/4 | 155/8 | 145/8 |

| Pre-bending capacity (mminches) | 145/8 | 131/2 | 129/16 |

| 49 Series | EVO 21049 | EVO 26049 | EVO 31049 |

|---|---|---|---|

| Rolls width (mminches) | 210082 | 2600102 | 3100122 |

| Rounding capacity (mminches) | 227/8 | 203/4 | 183/4 |

| Pre-bending capacity (mminches) | 183/4 | 175/8 | 165/8 |

| 71 Series | EVO 21071 | EVO 26071 | EVO 31071 |

|---|---|---|---|

| Rolls width (mminches) | 210082 | 2600102 | 3100122 |

| Rounding capacity (mminches) | 281 1/8 | 251 | 237/8 |

| Pre-bending capacity (mminches) | 237/8 | 213/4 | 203/4 |

| 102 Series | EVO 21102 | EVO 26102 | EVO 31102 |

|---|---|---|---|

| Rolls width (mminches) | 210082 | 2600102 | 3100122 |

| Rounding capacity (mminches) | 391 5/8 | 351 1/2 | 321 1/8 |

| Pre-bending capacity (mminches) | 321 3/8 | 291 1/4 | 271 |

| 139 Series | EVO 26139 | EVO 31139 | EVO 41139 |

|---|---|---|---|

| Rolls width (mminches) | 2600102 | 3100122 | 4100160 |

| Rounding capacity (mminches) | 421 5/8 | 381 1/2 | 331 1/8 |

| Pre-bending capacity (mminches) | 341 5/8 | 321 1/4 | 281 |

| 196 Series | EVO 26196 | EVO 31196 | EVO 41196 |

|---|---|---|---|

| Rolls width (mminches) | 2600102 | 3100122 | 4100160 |

| Rounding capacity (mminches) | 482 | 441 3/4 | 381 5/8 |

| Pre-bending capacity (mminches) | 411 5/8 | 381 3/8 | 341 1/4 |

| 283 Series | EVO 26283 | EVO 31283 | EVO 41283 |

|---|---|---|---|

| Rolls width (mminches) | 2600102 | 3100122 | 4100160 |

| Rounding capacity (mminches) | 652 3/4 | 602 3/8 | 522 1/16 |

| Pre-bending capacity (mminches) | 542 1/8 | 502 | 451 3/4 |

| 385 Series | EVO 26385 | EVO 31385 | EVO 41385 |

|---|---|---|---|

| Rolls width (mminches) | 2600102 | 3100122 | 4100160 |

| Rounding capacity (mminches) | 773 1/2 | 712 3/4 | 652 5/8 |

| Pre-bending capacity (mminches) | 652 5/8 | 602 3/8 | 542 1/8 |

| 513 Series | EVO 26385 | EVO 31385 | EVO 41385 |

|---|---|---|---|

| Rolls width (mminches) | 2600102 | 3100122 | 4100160 |

| Rounding capacity (mminches) | 943 5/7 | 863 2/5 | 753 |

| Pre-bending capacity (mminches) | 783 | 722 5/6 | 652 5/9 |

| 680 Series | EVO 31680 | EVO 41680 |

|---|---|---|

| Rolls width (mminches) | 3100122 | 4100160 |

| Rounding capacity (mminches) | 1034 | 903 1/2 |

| Pre-bending capacity (mminches) | 863 3/8 | 773 |

| 871 Series | EVO 31871 | EVO 41871 |

|---|---|---|

| Rolls width (mminches) | 3100122 | 4100160 |

| Rounding capacity (mminches) | 1184 5/8 | 1044 1/8 |

| Pre-bending capacity (mminches) | 1014 | 903 1/2 |

* Round bending capacity calculated with a yield strength of 260 MPa at a sheet width of 2000 mm, 2500 mm, 3000 mm or 4000 mm.

◊ Bending performance calculated with a yield strength of 260 MPa at a sheet width of 2000 mm, 2500 mm, 3000 mm or 4000 mm.

EVO 4-roll plate bending machine│Case Study: Apaco AG (Switzerland)

Perfect bending results with the EVO

for container construction in heating technology

Optional

equipment

HAEUSLER BENDTRONIC®

HAEUSLER’s revolutionary BENDtronic® enables anyone to control not only the movements of the machine but also the bending result itself. The software is graphically supported and allows bending in one or more passes. It can also be used for any type of product shape such as cylinders and tubes, ovals, tanks or other more complex geometries.

Fast reacting overrun brake for precise bending

The quick-reacting overrun brakes fitted as standard enable the operators to work very precisely. Furthermore, these brakes are an important safety factor, as they prevent plates from slipping out of the machine unintentionally.

Fast rolls rotation for increased productivity

The quick-reacting overrun brakes fitted as standard enable the operators to work very precisely. Furthermore, these brakes are an important safety factor, as they prevent plates from slipping out of the machine unintentionally.

Optional

equipment

Change rolls for bending small diameters

Exchangeable rolls enable our customers to bend even very small diameters. HAEUSLER machines are equipped in such a way that the roll in use is automatically recognized and the operating pressure is regulated accordingly.

Cone bending device, for bending conical parts

Allows continuous bending of conical parts with a cone angle greater than 5°.

Gas accumulator for calibration of welded cylinders

During the calibration process, the welded cylinder is clamped between the upper and lower rolls. While the cylinder rotates, the welded seam passes repeatedly between the top and bottom rolls. Due to the gas accumulator the lower roll adapts to the weld seam during rotation. This prevents overloading of the rolls bearings and the drive system.

Optional

Accessories

Upper support for simplified bending of large diameters

Upper supports simplify the bending of large diameters, since during the bending process the plate to be bent can be held and supported at 12 o’clock position.

Lateral support for simplified bending of large diameters

Lateral supports can be mounted on both sides of the machine and support the plate during bending.

Infeed roller table for quick and easy feeding of the plates into the machine

Infeed roller conveyors (optionally also with centering device) simplify the loading of the machine. Plates are deposited on the roller table and transported from there into the machine.

HAEUSLER

Product Overview

Experience the full HAEUSLER world. All products, all services, projects and more.

EVO applications

THE BENDING EVOLUTION.

Low operating costs, increased productivity and easy to use: The Haeusler EVO has a whole load of remarkable advantages. EVOs are frequently used in the following industries:

EVO: GET THE KNOW HOW

Get additional information about the world’s first bending machine with artificial intelligence.

HAEUSLER is certified

according to DIN EN ISO 9001.

TO THE CERTIFICATE