CMR Fullbody Pipe Expander│Hightech for your pipe mill

Full automation,

highest quality

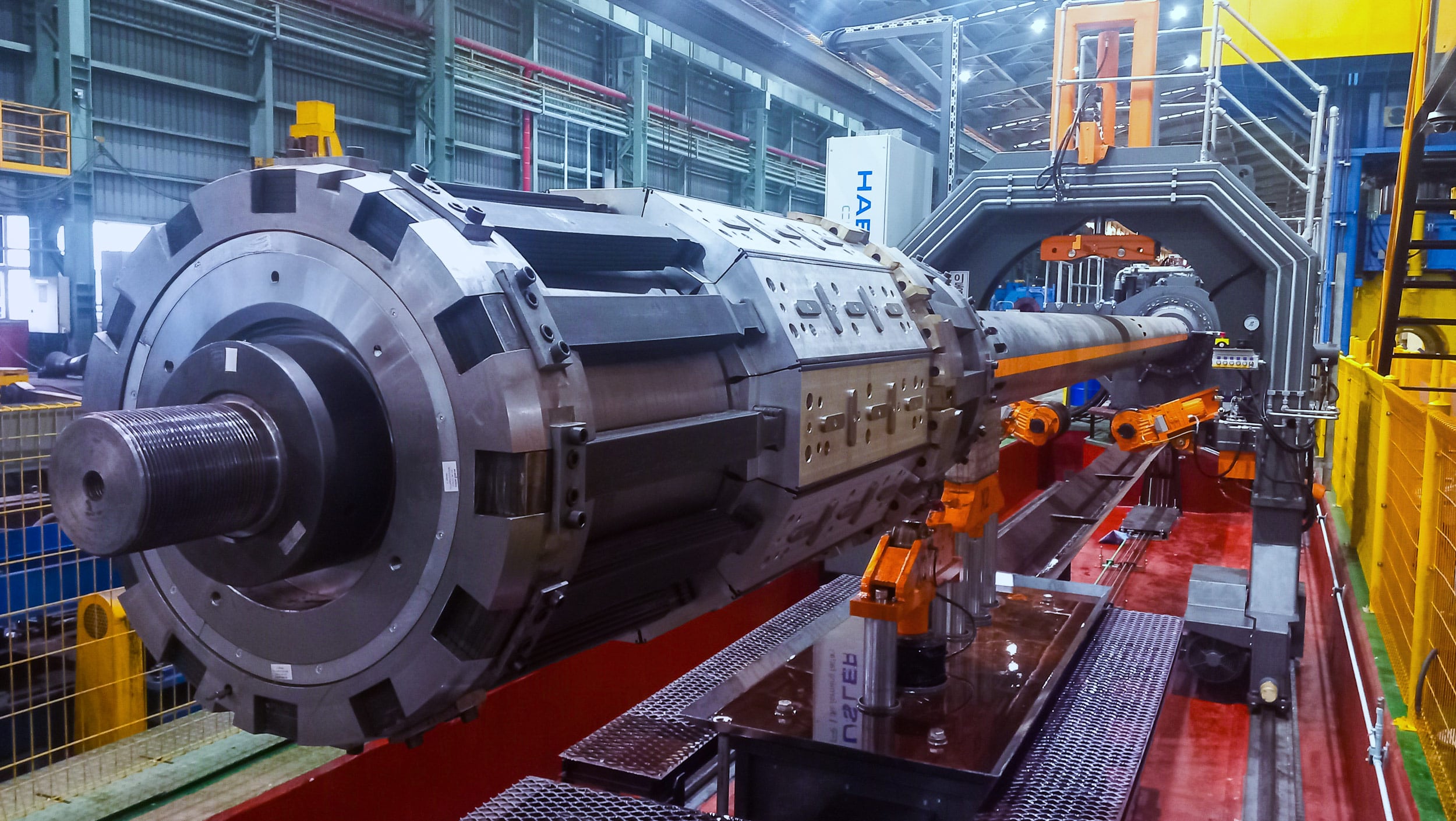

CMR Fullbody Pipe Expander

Complete equipment

at the final forming stage

Expanding is the final forming step in the production of pipe – it defines the final shape of the pipe and is necessary today to meet the required standards in LSAW Pipe Mills.

HAEUSLER offers the complete equipment including pre-washing system, expander, expander tools, post-washing and water treatment.

HAEUSLER offers the complete equipment including pre-washing system, expander, expander tools, post-washing and water treatment.

Advantages

at a glance

100% straight tubes

Closest tolerances

Minimal wear and tear

High output

CMR Fullbody Pipe Expander│Machines in Real-Life Operation

The final shaping

for high-end tubes

Features of the

HAEUSLER CMR

The development of the HAEUSLER CMR Fullbody Pipe Expander was mainly driven by the practical experience gained in HAEUSLER pipe mills worldwide. The HAEUSLER CMR combines all relevant features our customers have asked for in the production of high-end pipes.

Benchmark list:

- Largest possible contact surface on the cone

- Liner and cone assembly constantly in contact

- Rack and pinion drives

- No manual settings for setup

- hydraulically preloaded tool holder

- Individual lubrication lines on each segment

- Combined 4-chamber force and speed cylinder

- Pressure-controlled hydraulic pumps through LoadSensing

- Individual double stroke in automatic program

- Tool changing device Pipe measuring system

- Automatic straightness correction modes

100% straight pipes

The patented clamping weighers in combination with the software developed by HAEUSLER make it possible to expand every pipe in perfect quality.

Tightest tolerances

The variable process control developed by HAEUSLER allows the tightest tolerances to be achieved, even at the pipe ends.

Minimal wear

The unique expander head design combined with the intelligent Smart Lube Consumption System ensures minimal tool wear with the lowest possible oil consumption.

High output

The fully automated control of the machine, as well as the high speeds, enable an assured high output of the entire plant.

HAEUSLER

Product Overview

Experience the full HAEUSLER world. All products, all services, projects and more.

CMR applications

The HAEUSLER Fullbody Pipe Expander is especially used in the onshore and offshore industry.

Learn more?

In our download area you will find additional information about our products and services

HAEUSLER is certified

according to DIN EN ISO 9001.

Our reliable quality management according to DIN EN ISO 9001 ensures our customers a consistently high product and service quality.

TO THE CERTIFICATE