HAEUSLER WIND MILL│

The solution for windmill production

WINDMILLS

made with HAEUSLER

Our effective solutions

for your windmill production

Advantages at a glance

HAEUSLER WIND

Technical Concept

Windmill Equipment Features

HAEUSLER Products

Outperforming Gamechanger

Case Studies

Performance and service

Technical Concept

MAXIMIZE your opportunities

From sheet to section

with HAEUSLER

ARRIVAL OF NEW SHEETS

SHOTBLASTING OF SHEETS

INSPECTION

CUTTING OF SHEETS AND EDGE PREPERATION

MARKING FOR ACCESSORIES

4-ROLLER BENDING MACHINE ROLLING OF CAN, TACKING AND CALLIBRATION

2-4 WIRE SUB ARC WELDING STATION INTERNAL AND EXTERNAL SAW OF LONGITUDINAL SEAM

INSPECTION AND RELEASE OF CAN

ASSEMBLY OF SHELLS AND FLANGES, TACK WELDING AND SAW

PREPARATION OF NARROW GAP AND SAW

MACHINING OF WELD BEAD PAINTING AND

INSPECTION OF SECTIONS

SHOT BLASTING OF SECTION

PAINTING AND DRYING OF SECTIONS

INSPECTION AND ASSEMBLY OF BUILD IN COMPONENTS

FINAL INSPECTION AND RELEASE

Bending technology features

The innovations for your windmill production

Find out more about the HAEUSLER technology.

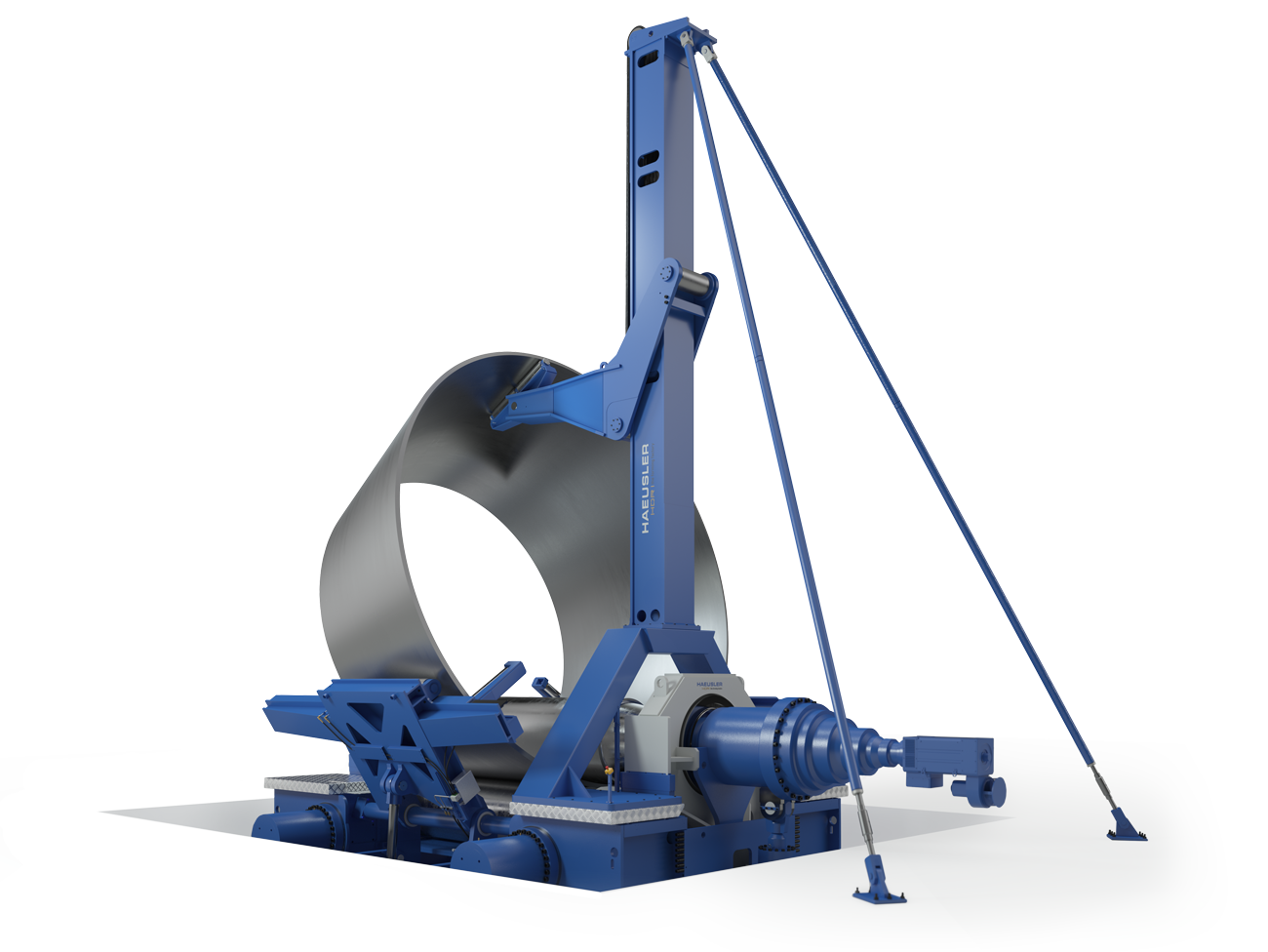

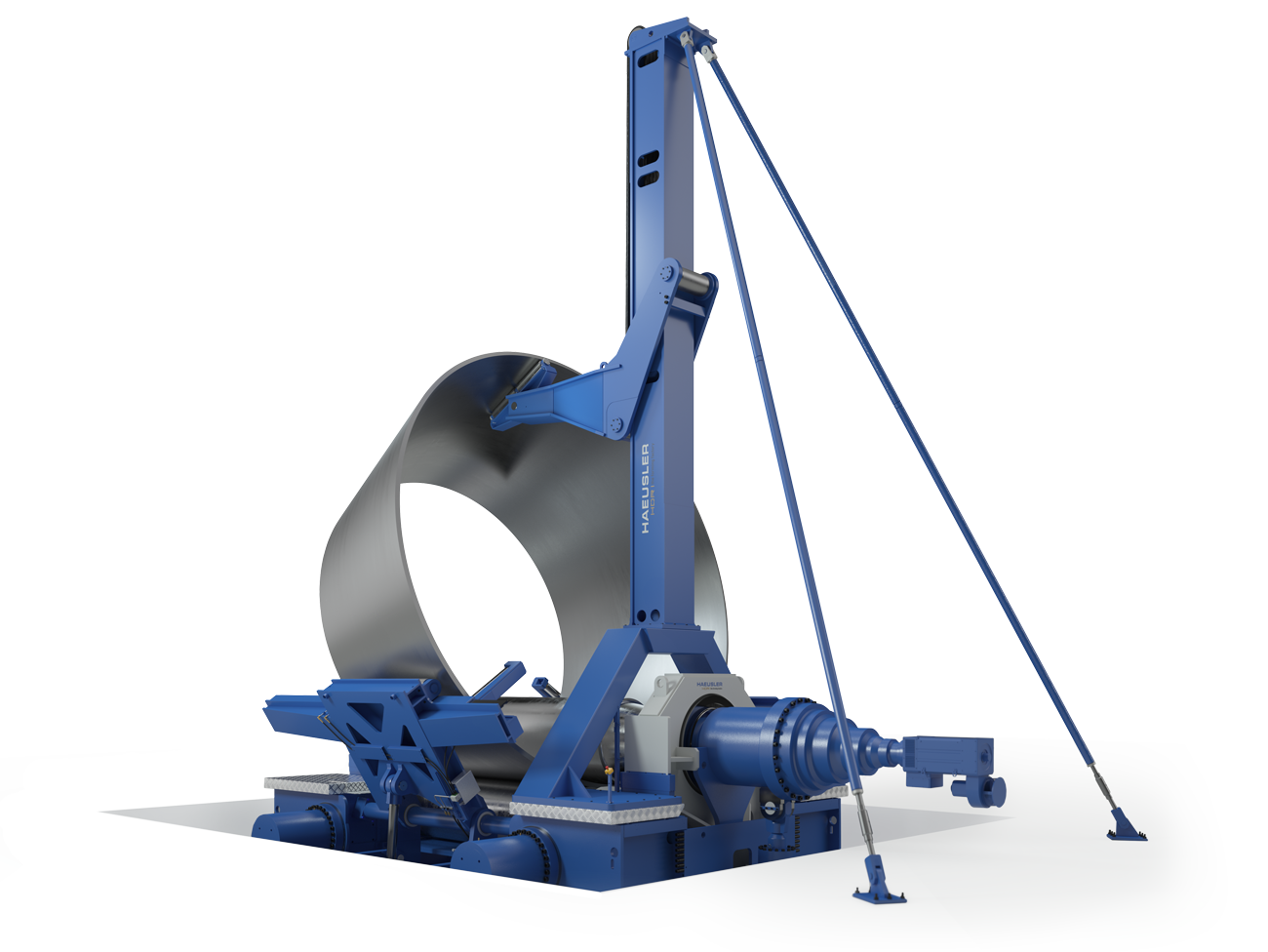

HAEUSLER calibration of cones

THE ONLY MACHINE that can calibrate cones

By inclining all three rollers, the cone can be brought into a position on the machine where it can be held stably. This allows continuous calibration of cones.

Cones can also be calibrated without manipulators.

Manipulators and the upper support ensure time saving in positioning the welded cone on the machine.

HAEUSLER EVO

Manufacturing Equipment

In addition to the actual bending machine, the accessories and the control system are of crucial importance!

Bending Machine

Depending on the intended use, different bending machines can serve as the basis for the additional accessories.

Upper Support WIND

Supports bending of workpieces with large diameters.

Laser measuring System

For quick checking and documentation of the roundness tolerances after calibration.

Side Support WIND

Thanks to the manipulators installed on the support, the parts to be bent can be optimally positioned.

Roller Table WIND

HAEUSLER has developed the WIND roller tables for fast loading and positioning of long plates in the machine.

HAEUSLER HDR

Power development with sensitivity

Best bending results

Due to the patented infeed of the top roller via four identical cylinders, absolute bending symmetry can be achieved - this is the basis for perfect bending results.

Highest accuracy

By using special T-slides in the drive and folding bearing stand, the guideways could be more than doubled compared to other suppliers. As a result, the highest accuracy can be permanently achieved during bending.

Optimum roller material

HAEUSLER uses only the most suitable roller material for our bending machines. The material is forged at our partner forges as close as possible to the final contour and then finally machined. This ensures that the properties created by the forging process are optimally transferred to the finished roll. For our customers, this means maximised service life.

Highest torques

By using rotary drives with very high torques, we enable our customers to finish their products in a few work steps and thus increase their productivity. In addition, all rotary drives are equipped with a fast-acting braking system as standard. This ensures precise and safe working.

Upper Support

Supports bending of workpieces with large diameters.

Easy maintenance

All main cylinders of the machine can be reached in a few simple steps and guarantee easy and quick maintenance.

Side Support

Thanks to the manipulators installed on the support, the parts to be bent can be optimally positioned.

Easy to operate

The menu navigation on the touch display is intuitive, the machine actively supports you during operation. All bending-relevant data can be displayed and adapted on the control.

HAEUSLER VRM

Offshore wind tower manufacturing plants

The VRM also ensures optimum results in the production of offshore windmills, among other things. It enables the bending of parts with particularly large diameters in an almost fully automatic process. Make your production of offshore windmills more efficient with HAEUSLER.

Plate Handling Station

HAEUSLER has developed the WIND roller tables for fast loading and positioning of long plates in the machine.

BENDtronic Control System

Bending becomes a child’s play with the best and most user friendly control.

4-Roll Bending Machine

The bending machine is the heart of your wind tower production. Together with the appropriate accessories, the sheets are formed into cylindrical or conical workpieces. With the help of the BENDtronic control system, this process runs almost fully automatically.

Side Support

Thanks to the manipulators installed on the support, the parts to be bent can be optimally positioned.

Upper Support

Supports bending of workpieces with large diameters.

Hybrid Drive System

HAEUSLER has invented the Direct Electric Drive, which combines lowest operating costs with maximum performance.

Virtual

Experience

HAEUSLER

UPPER SUPPORT – WIND

HAEUSLER UPPER SUPPORTS are modular and therefore available in a wide range of sizes and support heights. Capacity range from 0.5 t to 150 t supporting force / Supporting range from 1.5 m to 15.0 m.

The boom is pivot-mounted.

Special versions with cone retrieval system are available.

If requested, the upper support can also be fully integrated into the machine CNC.

HAEUSLER

SIDE SUPPORT – WIND

HAEUSLER SIDE SUPPORTS are available in a wide range of sizes. Capacity range from 2 t to 100 t supporting force.

Special manipulators are mounted to the side support. These manipulators optimally support the operator in bending, as well as in aligning the sheet ends before welding.

When bending conical workpieces, the sheet can be aligned with the help of the manipulators.

If requested, the side support including manipulators can also be fully integrated into the machine CNC.

HAEUSLER

ROLLER TABLE – WIND

There are basically two different types of HAEUSLER WIND ROLLER TABLES available:

- Roller tables that are firmly fixed to the floor (for plates > 80mm)

- Roller tables that can swivel during pre-bending (for plates up to 80mm)

Special manipulators are mounted to the roller table.

When bending conical workpieces, the sheet can be aligned with the help of the manipulators.

If requested, the roller table including manipulators can also be fully integrated into the machine CNC.

HAEUSLER

LASER MEASUREMENT SYSTEM

Simple and fast QUALITY CONTROL

Two laser distance sensors continuously measure the inner shell surface during calibration and create a graphic on the control system showing the deviation from the preselected tolerance and the position of the out-of-roundness. Operators can thus approach any out-of-roundness with pinpoint accuracy and check the result immediately.

Facts

Accuracy of Lasers = +- 0,5 mm

Accuracy of read out = +- 0,1 mm

Control and display = Integrated in control panel

Data exchange = PDF Document

During the calibration process, the operator can easily detect the out-of-round areas and correct the workpiece accordingly.

After calibration, the operator can easily and quickly generate a quality report.

HAEUSLER BENDtronic® BENDING BECOMES CHILD’S PLAY

- The revolutionary BENDtronic® from HAEUSLER makes it possible to control the bending result yourself.

- The software is graphically supported and allows bending in one or more passes.

- It can be used for any type of product shape such as cylinders and tubes, ovals, tanks or other more complex geometries.

Benefits

Big time saving

Quality assurance

Optimal support for cylindrical and conical parts

Realisation of fully automatic bending processes

Guiding of very strong cones

Easy operation and time saving

Windmill Production Machines

Your Choise for Quality

Find the right machine for your needs.

HDR 3-roll plate bending machine │ The universal plate bending machine

High performance

Multiple possibilities

- For heavy wall thicknesses

- Especially recommended for calibrating

- Even cones can be calibrated with this machine

- High working speeds and reliability

EVO 4-roll plate bending machine │ Bending becomes child’s play

Better than anything,

what you know…

- Best choice for wall thicknesses up to 80 mm

- High working speeds

- Low costs in acquisition and maintenance

- Highest reliability and intuitive control

VRM 4-roll plate bending machine │ High performance – always

Bending

in perfection

- Best choice for wall thicknesses above 80 mm

- High working speeds

- Best bending results with low maintenance costs

- Highest reliability and intuitive control

Virtual

Experience

Discover a HAEUSLER bending machine for windmill production in our virtual showroom.

Outperforming

Gamechanger

HAEUSLER bending machines are not only THE choice for a high quality production but also for the best economical performance.

HAEUSLER HHDS®

HIGHEST EFFICIENCY combined with

SUPERIOR PRODUCTIVITY

The HAEUSLER Hybrid Drive System HHDS® provides an unmatched efficiency due to the consequent usage of electrical motors in combination with planetary gearboxes. In practice this means savings of up to 50% of the running costs.

Additionally, the Hybrid Drive System allows a step-less adjustable rotation speed from 0 – 8 m/min. This is, compared to other machines that are available on the market, an increase of 60% and the basis for a high productivity.

WORKING SPEED IN COMPARISON

ENERGY COSTS IN COMPARISON

RUNNING COSTS

VERSUS WORKING SPEED

• More than 60% faster rotation speed

• Less than 50% operation costs

CONVENTIONAL

HYDRAULIC DRIVE

Roll adjustment and rotation are actuated hydraulically

- high oil volume required

- system is always running

- high running costs

- limited rotation speed (due to oil-volume)

- efficiency of system ~ 60%

HAEUSLER’S HIGH EFFICIENT

HYBRID DRIVE SYSTEM

roll adjustment and rotation are actuated independently

- low oil volumne required

- system is only running if necessary

- low running costs

- high rotation speed

- efficiency of system ~ 85%

HAEUSLER VSA®

Allows bending of thicker plates

and smaller diameters

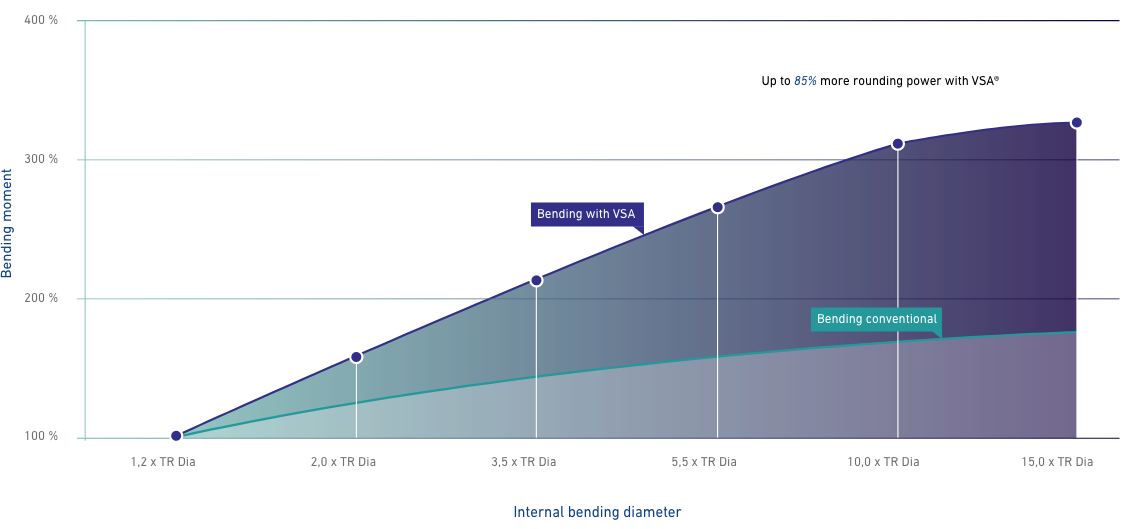

The new and patented VSA® – technology allows the operator to bend either very heavy wall thicknesses or alternatively very small diameters. This can be realized by a unique adjustment of the bending geometry.

By using two instead of only one pivot point for each side roll swing arm fixation, the machine can individually be adjusted either to create a wide bending geometry for heavy wall thicknesses or a tight geometry if small diameters shall be bent.

The EVO is worldwide the only 4-roll plate bender with this unique feature. For our clients it means that they are now in a position to get a machine with up to 85% more bending moment compared to conventional bending machines.

HAEUSLER VSA® –

SHIFTING UP THE LIMITS

FLEXIBILITY VERSUS OUTPUT

• Up to 85% more rounding power – “EVO can bend thicker plates”

• No geometrical limitations – “EVO can bend very small diameters”

• Changing geometry is done in minutes

THE INSPIRED IDEA BEHIND

THE VSA TECHNOLOGY

Two pivot points are better than one

Performance

has a reason

With HAUESLER equipment you significantly reduce running costs and therefore increase your economical output. That‘s the true value of HAEUSLER bending machines.

Attractive financing options

IN COOPERATION WITH OUR PARTNERS

FOR TENORS LESS THAN 24 MONTHS:

- No down payment necessary

- Montly, quarterly or half-yearly installments

- Or bullet payment after 23 months

- 15% down payment

- Rest to be paid in equal half-yearly installments

Initial Investment

Windmill Presentation

Take advantage of our cost free online presentation and learn more about performance based windmill production with HAEUSLER.

Convincing

The benefit of

HAEUSLER project management

To work with only one contract partner makes the execution and project supervision for you lean and easy. You can concentrate on your core business.

Based on our more than 80 years’ experience in international projects and partnerships with premium producers, you will get a plant according latest state of the art, to fair commercial conditions.

During the project the whole responsibility of success is with HAEUSLER. In no event there will be a lack of responsibility due to unclear interfaces in between the single stations. You do not buy equipment you purchase a complete solution.

HAEUSLER

Product Overview

Experience the full HAEUSLER world. All products, all services, projects and more.

HAEUSLER’s

supplementary services

- Plant engineering

- Basic engineering for all media networks like water, air, power, cooling systems and technical gases

- Civil engineering documents

- Basic engineering for grounding

- Basic engineering for drain systems and waste water treatment

- Quality Assurance Laboratory

- Maintenance workshop

- Spare parts logistics

- Consumables

- Transport and lifting equipment

- Site management and installation

- Training

- Production support

- Repair services

- Certification support

- Plant modernisation

HAEUSLER is certified

according to DIN EN ISO 9001.

Our reliable quality management according to DIN EN ISO 9001 ensures our customers a consistently high product and service quality.