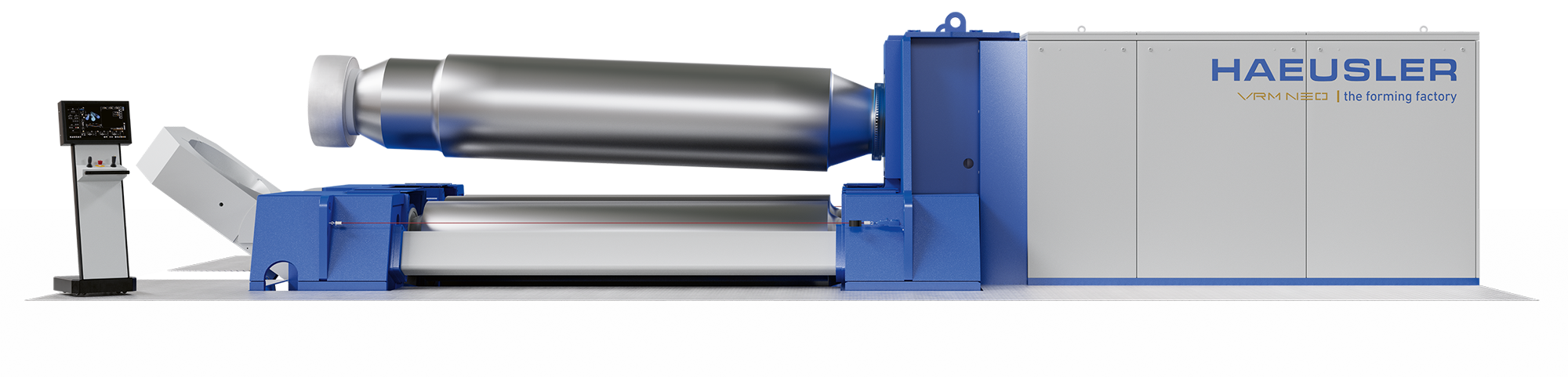

VRM NEO 4-roll bending machine │Bending with a competitive edge

MORE PRODUCTIVE,

EFFICIENT,

INTELLIGENT

VRM NEO 4-roll bending machine │Bending with a competitive edge

PERFECTS YOUR PRODUCTION

WITH SMART CONTROL

Advantages

at a glance

Up to 40% cost savings

70% more productivity

Up to 30% energy savings

Intelligent BENDtronic control system

Innovative functions

for maximum efficiency

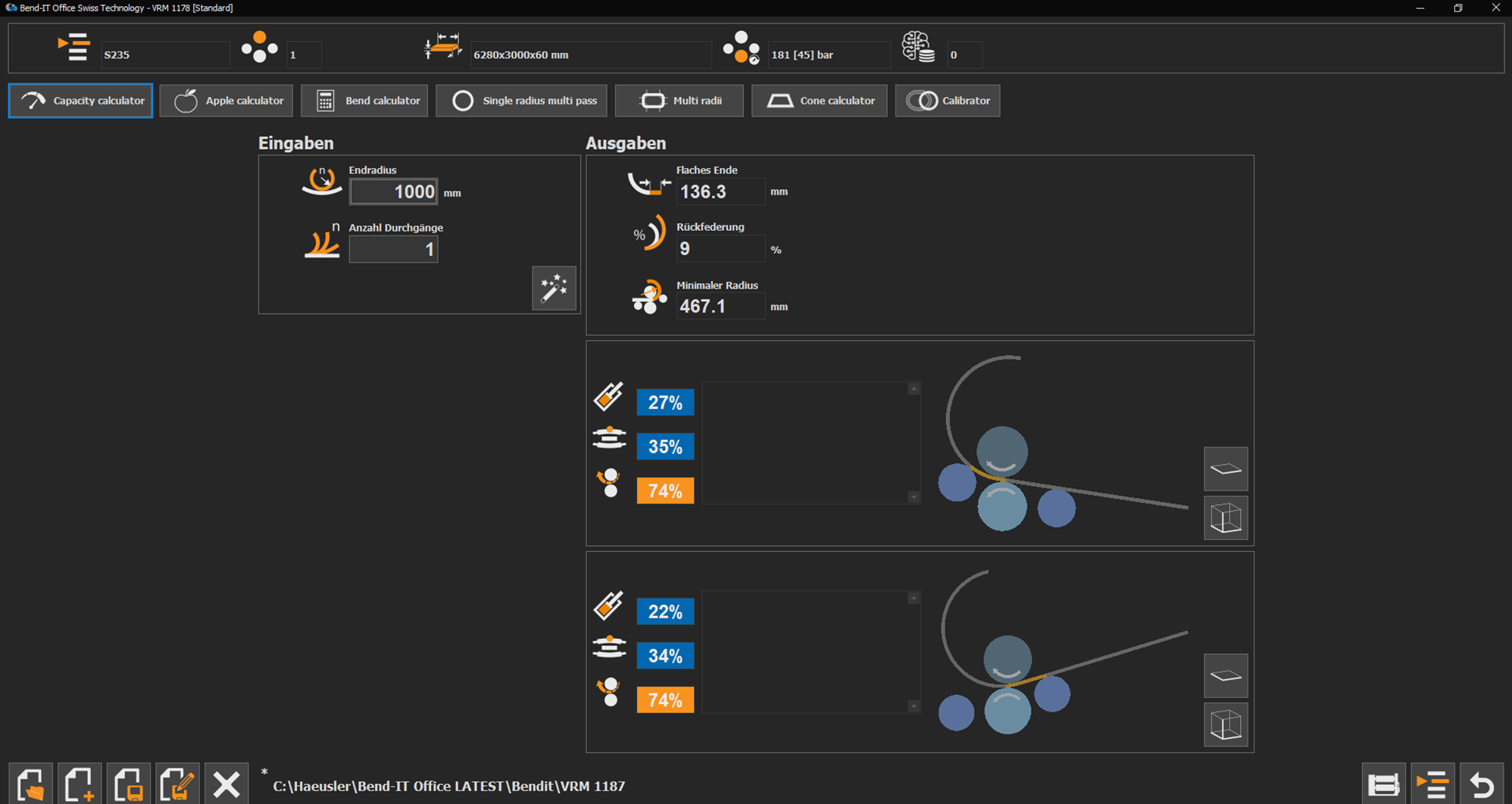

BENDtronic control system

Thanks to the BENDtronic® control system, work preparations can be carried out optimally. Individual steps or the entire bending process can be simulated and prepared.

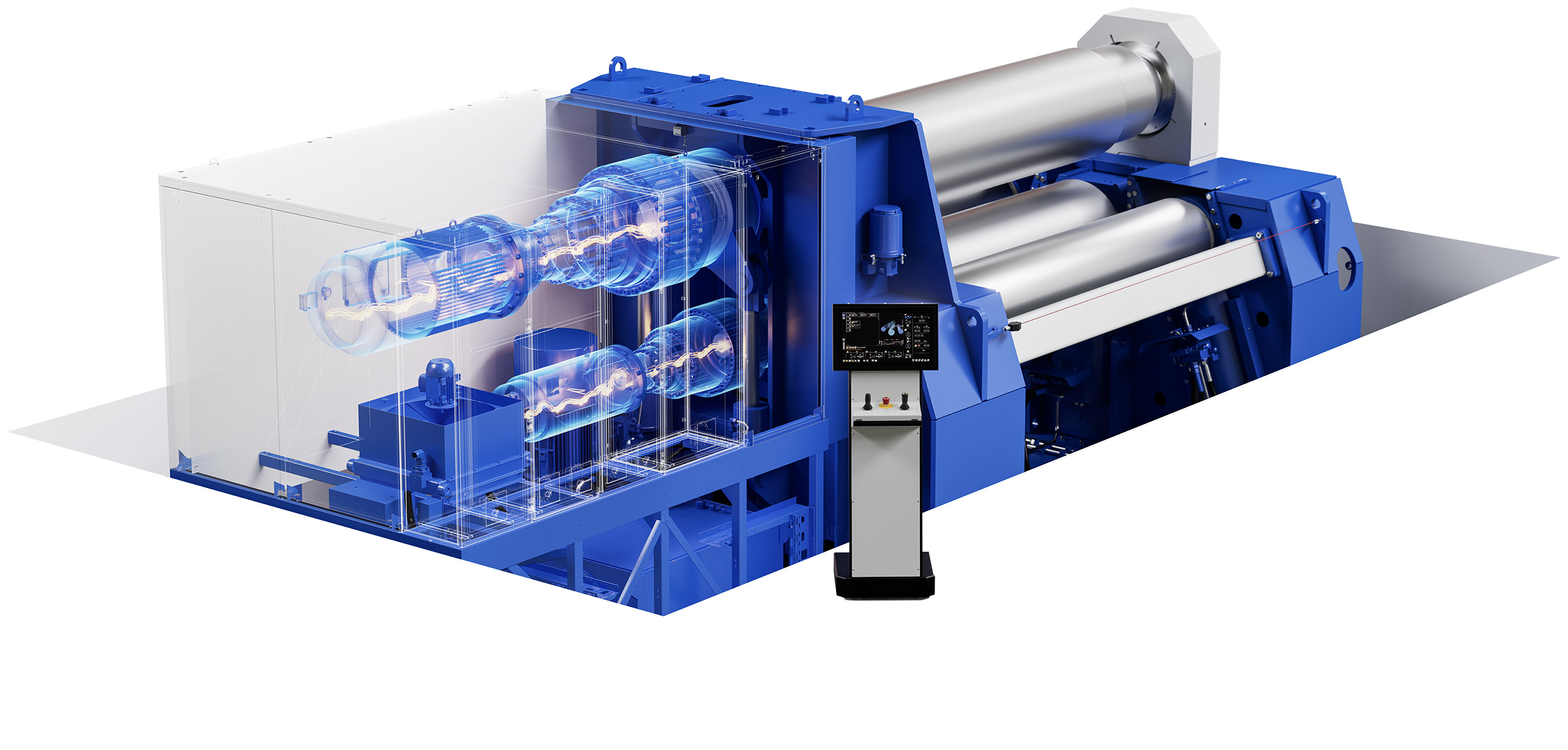

Electric drive

The electric drive of the VRM NEO is designed to drastically reduce energy consumption. Through the use of modern drive technologies the power consump-tion is optimized, which significantly reduces operating costs.

Energy-Saving Hydraulics

The integrated energy-saving hydraulic system uses demand-based pump control by means of load sensing, which precisely adjusts the energy input to the actual demand. In addition, the flow sharing technology ensures intelligent oil management

for optimal use of the oil output.

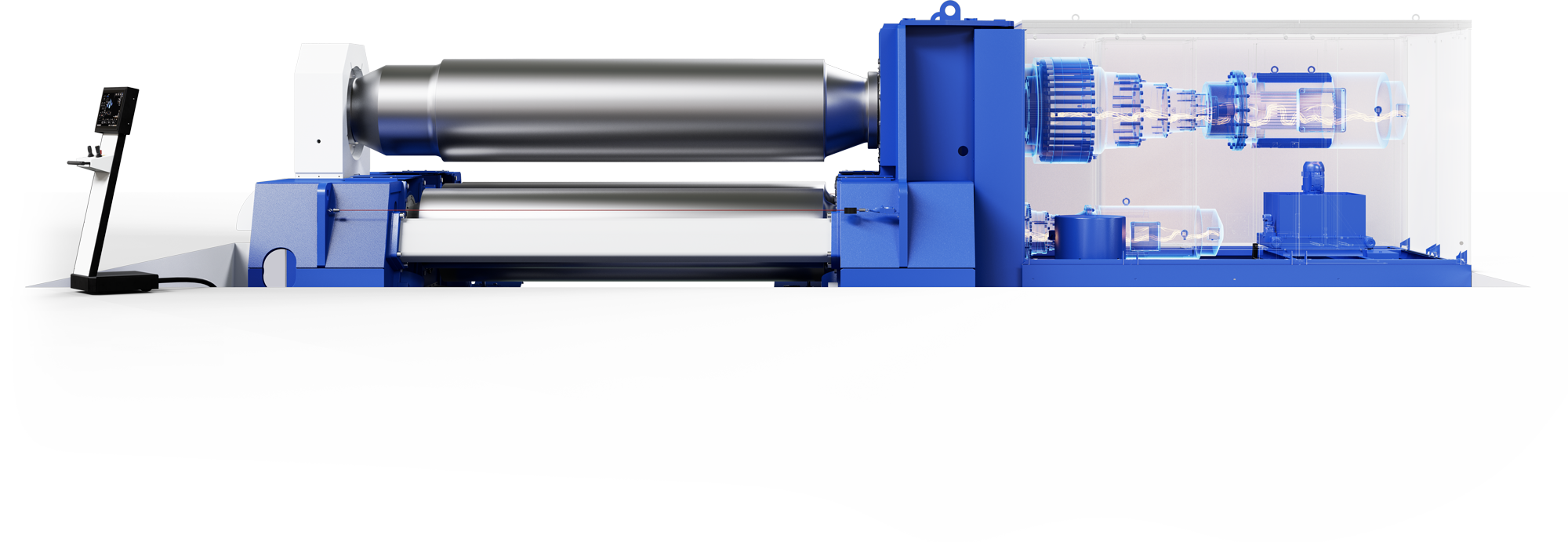

Linear Guidance

The extended linear guidance of the side roller positioning offers exceptional flexibility in production by combining stability, durability and low downtime with minimal space requirements.

Flexible roller change

The ability to switch quickly between different roller diameters, significantly increases the flexibility of production and makes it possible to fulfill different order requirements.

MAXIMUM ENERGY EFFICIENCY

THANKS TO THE HYBRID CONCEPT

TOTAL COST OF OWNERSHIP

CALCULATE INDIVIDUALLY NOW

The TCO calculator for the VRM NEO 4-roll bending machine precisely calculates the total cost of ownership based on your inputs, helping you to analyse costs over the years and make efficient decisions.

HIGH FLEXIBILITY

WITH MAXIMUM THROUGHPUT

THANKS TO ROTATION SPEED &

4-ROLLER CONCEPT WITH LINEAR GUIDANCE

PRODUCT RANGE

SIZES AND WALL THICKNESSES

DISCOVER MORE

MACHINE RANGE

VRM NEO IS SELECTION

The following sizes are available as standard with short delivery time.

| 680 Series | VRM NEO 3050-680VRM NEO 3100-680 | VRM NEO 4050-680 |

|---|---|---|

| Rolls width (mminches) | 3050122 | 4050159 |

| Rounding capacity (mminches) | 953 3/4 | 853 3/8 |

| Pre-bending capacity (mminches) | 773 | 682 5/8 |

| 871 Series | VRM NEO 3050-871VRM NEO 3100-871 | VRM NEO 4050-871 |

|---|---|---|

| Rolls width (mminches) | 3050122 | 4050159 |

| Rounding capacity (mminches) | 1134 1/2 | 1214 |

| Pre-bending capacity (mminches) | 913 5/8 | 813 1/4 |

| 1178 Series | VRM NEO 3050-1178VRM NEO 3100-1178 | VRM NEO 4050-1178 |

|---|---|---|

| Rolls width (mminches) | 3050122 | 4050159 |

| Rounding capacity (mminches) | 1345 1/4 | 1214 3/4 |

| Pre-bending capacity (mminches) | 1084 1/4 | 973 7/8 |

| 1374 Series | VRM NEO 3050-1374VRM NEO 3100-1374 | VRM NEO 4050-1374 |

|---|---|---|

| Rolls width (mminches) | 3050122 | 4050159 |

| Rounding capacity (mminches) | 1495 7/8 | 1325 1/4 |

| Pre-bending capacity (mminches) | 1204 3/4 | 1074 1/4 |

| 1585 Series | VRM NEO 3050-1585VRM NEO 3100-1585 | VRM NEO 4050-1585 |

|---|---|---|

| Rolls width (mminches) | 3050122 | 4050159 |

| Rounding capacity (mminches) | 1646 1/2 | 1445 5/8 |

| Pre-bending capacity (mminches) | 1335 1/4 | 1164 5/8 |

| 1811 Serie | VRM NEO 3050-1811VRM NEO 3100-1811 | VRM NEO 4050-1811 |

|---|---|---|

| Rolls width (mminches) | 3050122 | 4050159 |

| Rounding capacity (mminches) | 1787 | 1576 1/8 |

| Pre-bending capacity (mminches) | 1445 5/8 | 1285 |

Optional equipment

HAEUSLER BENDTRONIC®

HAEUSLER’s revolutionary BENDtronic® enables anyone to control not only the movements of the machine but also the bending result itself. The software is graphically supported and allows bending in one or more passes. It can also be used for any type of product shape such as cylinders and tubes, ovals, tanks or other more complex geometries.

Highest rotation speed

Ethernet connection for online access

Online access enables our service engineers to access our customers’ roll bending machines in the shortest possible time and ensure optimum support.

Optional

equipment

Autonomous bending

With the help of the system’s intelligent information feedback, an autonomous bending process is possible from the first sheet without rejects and operator influence.

Cone bending device, for bending conical parts

Allows continuous bending of conical parts with a cone angle greater than 5°.

Gas accumulator for calibration of welded cylinders

During the calibration process, the welded cylinder is clamped between the top and bottom rollers. The weld seam passes through the rollers repeatedly, with the gas accumulator taking over the adjustment of the bottom roller and preventing the system from being overloaded.

Optional

accessories

Upper Support

Upper supports simplify the bending of large diameters, since during the bending process the plate to be bent can be held and supported at 12 o’clock position.

Lateral Support

Lateral supports can be mounted on both sides of the machine and support the plate during bending.

Roller Conveyors

Infeed roller conveyors (optionally also with centering device) simplify the loading of the machine. Plates are deposited on the roller table and transported from there into the machine.

VRM NEO Applications

WORLDWIDE FOR EVERY APPLICATION

VRM NEO: GET THE KNOW HOW

Get additional information about the 4-plate bending machine with its intelligent control system and energy-saving drive.