VRM 4-roll plate bending machine │Bending becomes child’s play

High performance, – always…

VRM 4-roll plate bending machine │Bending becomes child’s play

Bending

in perfection

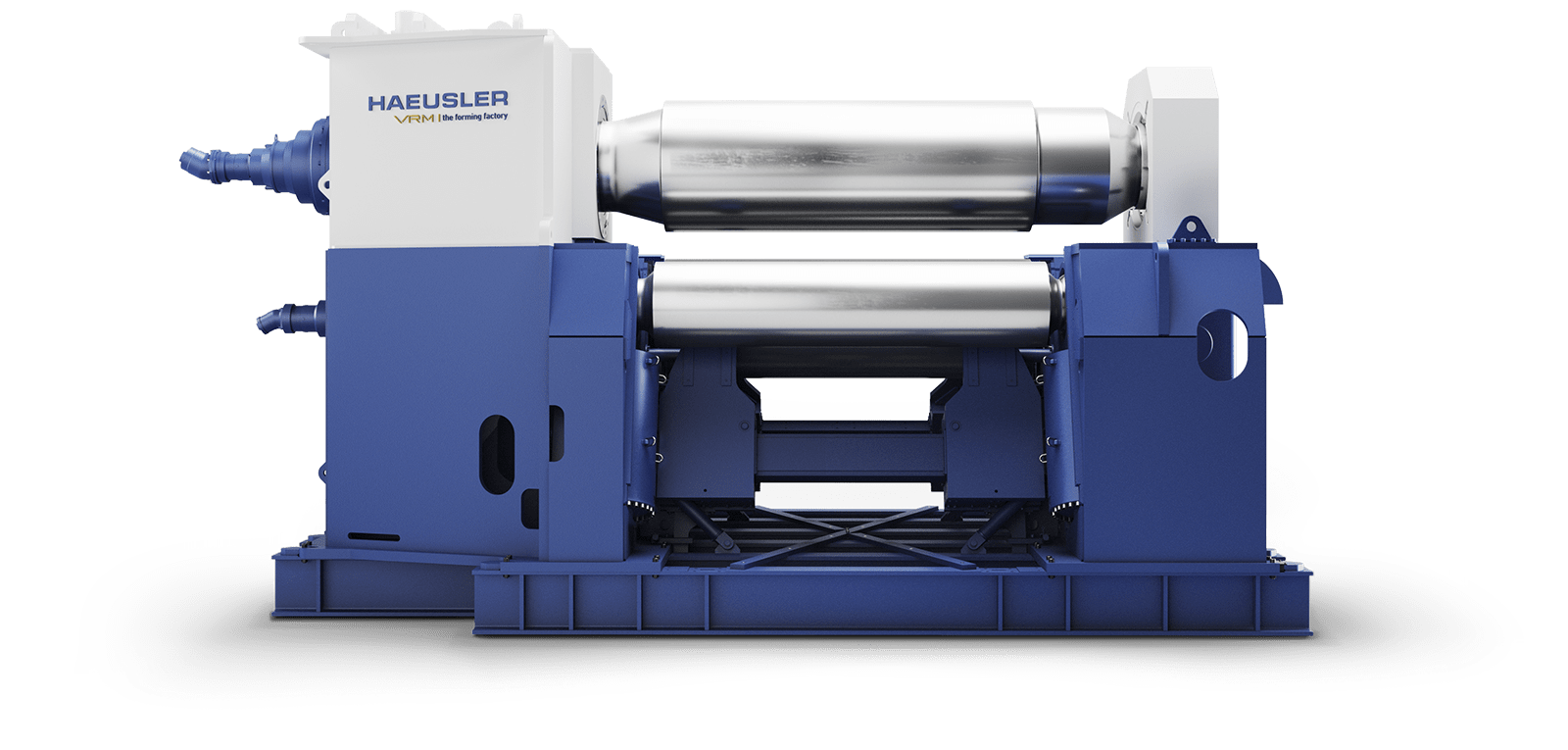

Optimum bending geometry and perfect suitability for bending conical parts. The Haeusler VRM has been the absolute class leader in the field of 4-roll bending machines for decades. Renowned customers worldwide swear by the advantages of the Haeusler VRM.

Advantages at a glance

Highest torques

Very high accuracy

Optimum roll material

Perfect bending results

Bending becomes child's play

VRM 4-roll plate bending machine │Machines in Real-Life Operation

Proven classic in

round bending technology

Developed

for continuous use

The Haeusler VRM 4-roll plate bending machine was developed for “HEAVY DUTY” use. 365 days – 24 hours, the Haeusler VRM always does its job. In addition, the optimised bending geometry allows the smallest possible bending ends to be realised. The VRM bending machine is the result of more than 50 years of continuous development work. Coupled with the new patented Haeusler BENDtronic® control system, it is now the benchmark for 4-roll bending machines. Of course in proven Haeusler quality – Swiss made.

Highest torques

By using rotary drives with very high torques, we enable our customers to finish their products in just a few work steps and thus increase their productivity. In addition, all rotary drives are equipped with a fast-acting braking system as standard. This ensures precise and safe working.

Very high accuracy

Due to the special and patented arrangement of the side roller cylinders, the guideways could be more than doubled compared to other suppliers. As a result, the highest bending accuracies can be permanently achieved and wear reduced to a minimum.

Optimum roller material

HAEUSLER uses only the most suitable roller material for our bending machines. The material is forged at our partner forges as close as possible to the final contour and then finally machined. This ensures that the properties created by the forging process are optimally transferred to the finished roll. For our customers, this means maximised service life.

Perfect bending results

The optimised bending geometry of the HAEUSLER VRM enables the bending of the narrowest diameters with the smallest possible bending ends at the same time. In addition, this bending geometry has also been optimised for bending conical components.

Bending becomes child's play

The latest generation of HAEUSLER's patented BENDtronic 2.0 control with integrated artificial intelligence enables the operator to achieve perfect bending results right from the start.

Efficient bending

with the VRM 4-roll plate bending machine

The VRM 4-roll plate bending machine makes bending processes child’s play. This already starts with the alignment of the sheet at the outlet side roller: The sheet is automatically optimally aligned by the machine, which saves the use of lifting gear and auxiliary personnel. During the entire bending process, there is no idle movement of the workpiece due to the bending of both ends of the sheet in the same pass.

Also, the VRM bending machine does not require the sheet to be aligned twice, as is the case with 3-roll machines, due to the automatic bending of the second end of the sheet – the sheet therefore remains clamped between the upper and lower rolls during the entire bending process. The machine automatically adjusts the straight remaining cylinder end to the shortest possible dimension. This saves you work steps.

Safe drive thanks to 4 rollers

The drive of the VRM 4-roll round bending machine by upper and lower rolls offers enormous advantages during the bending process: Even when bending the thinnest sheets, the workpiece is optimally transported. The sheet is securely clamped between the top and bottom rollers – there is no chance of the sheet slipping on the rollers.

The fact that all four rollers are mounted on roller bearings means that there are no lubrication problems in the roller bearings. Therefore, no frictional power has to be dissipated in the form of heat, as is the case with plain bearings. So you don’t need to worry about any friction that may occur.

Centralised control

The operation of the VRM 4-roll plate bending machine is also very efficient: the complete bending process can be operated by just one person via a central, mobile control panel. All control elements are brought together there. In addition, the bending machine can be operated and controlled from both sides – the control panel does not have to be left for this purpose.

Automation of the bending machine

The hydraulic system of the VRM sheet bending machine automatically regulates the speed compensation between the upper and lower rolls. This ensures that the two rollers always roll optimally on the sheet metal to be bent. At the same time, the pressure relief valves protect the machine from overload. Thus, the bottom roller lowers itself according to the sheet thickness even with double sheet entry.

In addition, an automatic pressure compensation system for the bottom roller is installed in the VRM 4-roller round bending machine. This means that the same pressures always prevail at both ends of the cylinder to be rounded and the cylinder diameter is thus the same at both ends – for an optimum result.

VRM 4-roller round bending machine in detail

The VRM 4-roll round bending machine has many more advantages to offer. In the white paper you will learn more about the advantages of the VRM machine and the bending process. With the help of clear graphics, you will get to know the VRM in detail and see the bending process with your own eyes.

More details about

round bending with VRM?

Discover the HAEUSLER VRM bending machine in our white paper.

VRM 4-roll plate bending machine │ Case Study: Dajin Offshore (China)

Innovative handling for gigantic monopiles

High-performance circular bending for Dajin Offshore

The VRM bends huge monopile shots at Dajin Offshore with high precision and perfect handling.

With a rotation speed of 8 m/min and an innovative handling system, the VRM achieves particularly high productivity.

Standard equipment

Automatic central grease lubrication for easy maintenance

The use of automatic centralised grease lubrication means that all relevant points on the roll bending machine are lubricated automatically.

Fast reacting overrun brake for precise bending

The fast-acting overrun brakes fitted as standard enable the operator to work very precisely. These brakes are also an important safety factor, as they prevent sheets from slipping out of the roll bending machine unintentionally.

Ethernet connection for online access

Online access enables our service engineers to access our customers’ roll bending machines in the shortest possible time and guarantee optimum support.

Optional equipment

Change rolls for bending small diameters

Exchangeable rolls enable our customers to bend even very small diameters. HAEUSLER machines are equipped in such a way that the roll in use is automatically recognized and the operating pressure is regulated accordingly.

Cone bending device, for bending conical parts

Allows continuous bending of conical parts with a cone angle greater than 5°.

Gas accumulator for calibration of welded cylinders

During the calibration process, the welded cylinder is clamped between the upper and lower rolls. While the cylinder rotates, the welded seam passes repeatedly between the top and bottom rolls. Due to the gas accumulator the lower roll adapts to the weld seam during rotation. This prevents overloading of the rolls bearings and the drive system.

Optional accessories

Upper support for simplified bending of large diameters

Upper supports simplify the bending of large diameters, as the shot to be bent can be held and supported at the 12 o’clock position during the bending process.

Lateral support for simplified bending of large diameters

Lateral supports can be mounted on both sides of the machine and support the plate during bending.

Infeed roller table for quick and easy feeding of the sheets into the roll bending machine

Infeed roller conveyors (optionally also with centring device) simplify the loading of the machine. Plates are placed on the roller table and transported from there into the round bending machine.

HAEUSLER

Product Overview

Experience the full HAEUSLER world. All products, all services, projects and more.

VRM applications

Bending to perfection.

The Haeusler VRM has been the benchmark in the field of 4-roll plate bending machines for decades. Extremely versatile and absolutely reliable. For this reason VRMs are very often used in the following industries:

Learn more?

Further information about HAEUSLER VRM can be found in our product brochure.

FAQ

Important questions about

the VRM 4-roll round bending machine

The VRM 4-roll plate bending machine from HAEUSLER sets new standards in metal processing. In this FAQ, we answer the most frequently asked questions and provide detailed information about the features, advantages, and maintenance requirements of this advanced machine.

What are the main features of the VRM 4-roll plate bending machine?

The VRM 4-roll plate bending machine features a robust, torsion-resistant design that ensures high precision and bending quality. It is ideal for industrial applications and can bend materials with high yield strength and small radii. The machine offers a compact design that does not transfer dynamic process forces to the foundation.

What advantages does the HAEUSLER VRM 4-roll plate bending machine offer compared to other machines?

The VRM 4-roll bending machine allows bending without idle movements and with automatic alignment of the sheet. Thanks to the linear roll adjustment, it offers high bending accuracy and repeatability. All four rolls can be driven and tilted, which facilitates cone bending. The machine can efficiently handle plates of different thicknesses and sizes.

How does the bending process of the VRM 4-roll plate bending machine work?

The bending process involves several steps: raising the rolls, centering the sheet, and pre-bending both ends in a single pass. The sheet remains clamped between the top and bottom rolls throughout the bending process, ensuring precise and uniform bending. This process reduces the need for lifting equipment and additional labor, as the sheet is automatically aligned and bent.

How often does the bending machine need to be serviced?

Regular maintenance of the VRM 4-roll bending machine is recommended every six months to ensure optimal performance. The machine is equipped with automatic central lubrication and fast-acting brakes, which simplify maintenance. Additionally, the rolls are mounted on roller bearings, minimizing friction and increasing durability.

Is there training for operating the machine?

Yes, HAEUSLER offers comprehensive training for the operation and maintenance of the VRM 4-roll plate bending machine to ensure that operators can use the machine efficiently and safely. These training sessions cover the operation of the central control panel as well as the adjustment and maintenance of the machine.

What material are the rolls of the VRM 4-roll plate bending machine made of?

This mightinterest you

4-roll plate bending machine

Get to know the complete range of our 4-roll plate bending machines.

DISCOVER MORE

Downloads & Media

Download additional material on our products and services.

DISCOVER MORE.

HAEUSLER is certified

according to DIN EN ISO 9001.

TO THE CERTIFICATE