RMS 3-roll pipe bending machine│For efficient pipe bending

High Productivity

Flexible in use

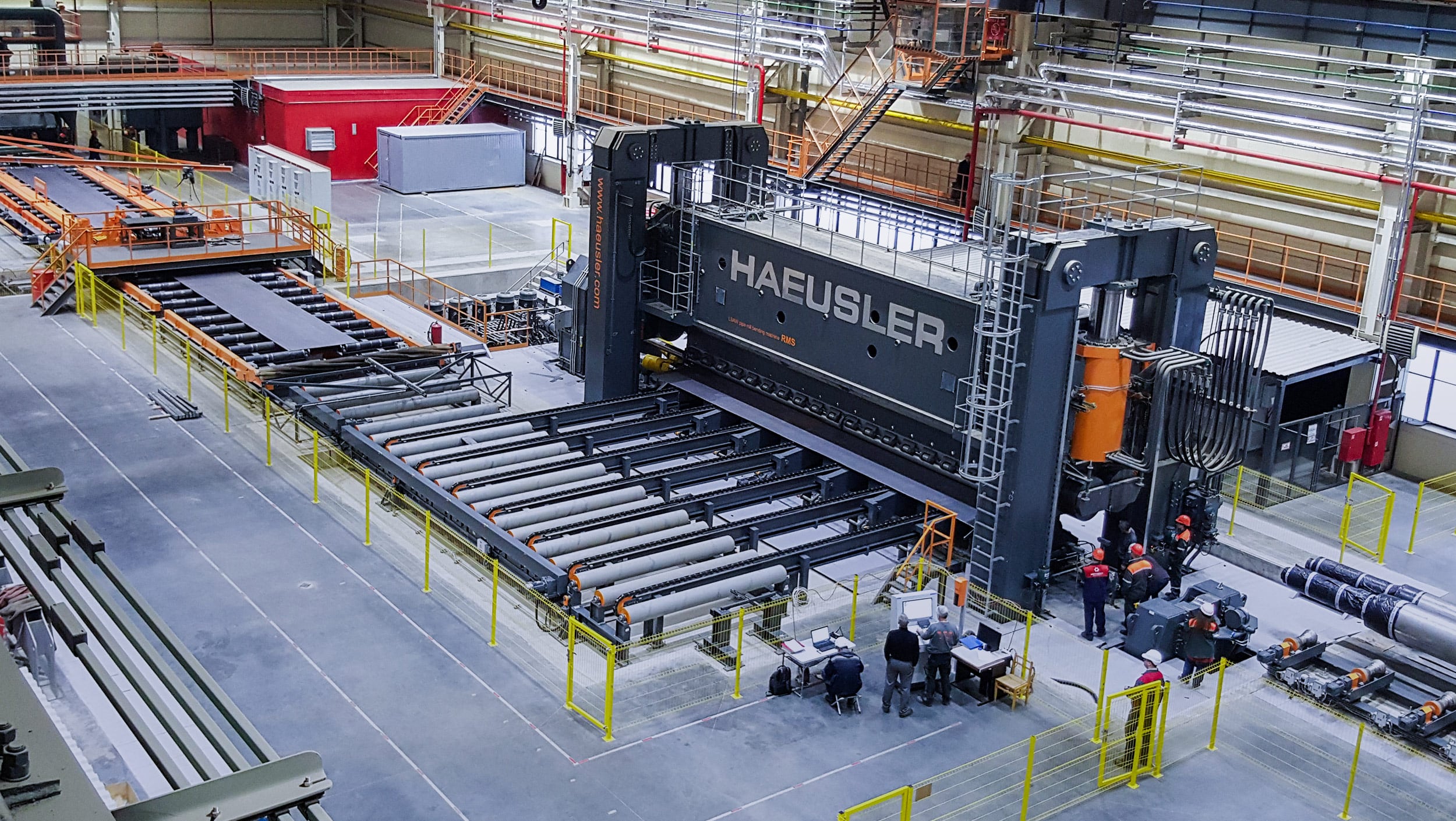

RMS 3-roll pipe bending machine

Pipe bending

The right process for every pipe mill

Only the HAEUSLER RMS offers three different bending processes: bending with a pre-tensioned top roll, bending with a supported top roll, and press bending.

Thanks to this versatility and HAEUSLER’s renowned quality, the RMS is perfect for industrial applications in bending steel pipes and round pipes.

Advantages

at a glance

Highest bending quality

Flexible production

Very high output

Simple & comfortable

RMS 3-roll pipe bending machine │ Machines in Real-Life Operation

Fast, precise, versatile

Pipe manufacturing with maximum flexibility

High productivity & flexibility

in pipe bending

Highest bending quality through continuous forming process

Compared to other forming processes, the roll bending process offers a continuous and homogeneous application of force into the plate to be bent. This avoids stress peaks in the formed pipe and ensures the best possible pipe quality.

Very high output

Due to the fully automated roll bending process, including plate and pipe handling, cycle times of less than 3 minutes per pipe can be realized. This ensures a reliable and calculable output of the entire plant.

Flexible production possibilities

The roll bending process offers the great advantage that the complete production portfolio in the LSAW pipe mill range (16

Simple operation and high degree of automation

The fully automatic machine control developed by HAEUSLER enables our customers to achieve perfect bending results with only a few steps.

HAEUSLER

Product Overview

Experience the full HAEUSLER world. All products, all services, projects and more.

Standard equipment

Automatic central grease lubrication for easy maintenance

Fast reacting overrun brake for precise pipe bending

The standard-built, fast-reacting back-up brakes enable precise pipe bending and enhance safety by preventing pipes or plates from unintentionally slipping out of the pipe bending machine.

Ethernet connection for online access

The Ethernet connection allows our service engineers to quickly access our customers’ tube bending machine and provide optimal support, maximising uptime and minimising downtime.

RMS applications

The heart of pipe production

The HAEUSLER RMS 3-roll plate bending machine is primarily used in LSAW pipe mills for the production of pipelines for both onshore and offshore applications.

FAQ

Important questions

to RMS pipe bending machine

How does the RMS 3-roll pipe bending machine improve pipe bending processes in LSAW pipe production?

What technical advantages does the RMS offer for bending steel pipes in offshore projects?

Why is the RMS ideal for efficient production in the onshore and offshore industries?

How does the automation of the RMS 3-roll pipe bending machine support product longevity?

What bending methods are supported by the RMS?

Learn more?

In our download area you will find additional information about our products and services

HAEUSLER is certified

according to DIN EN ISO 9001.

TO THE CERTIFICATE