HDR 3-roll plate bending machine│The universal sheet metal bending counter

High performance

Multiple possibilities

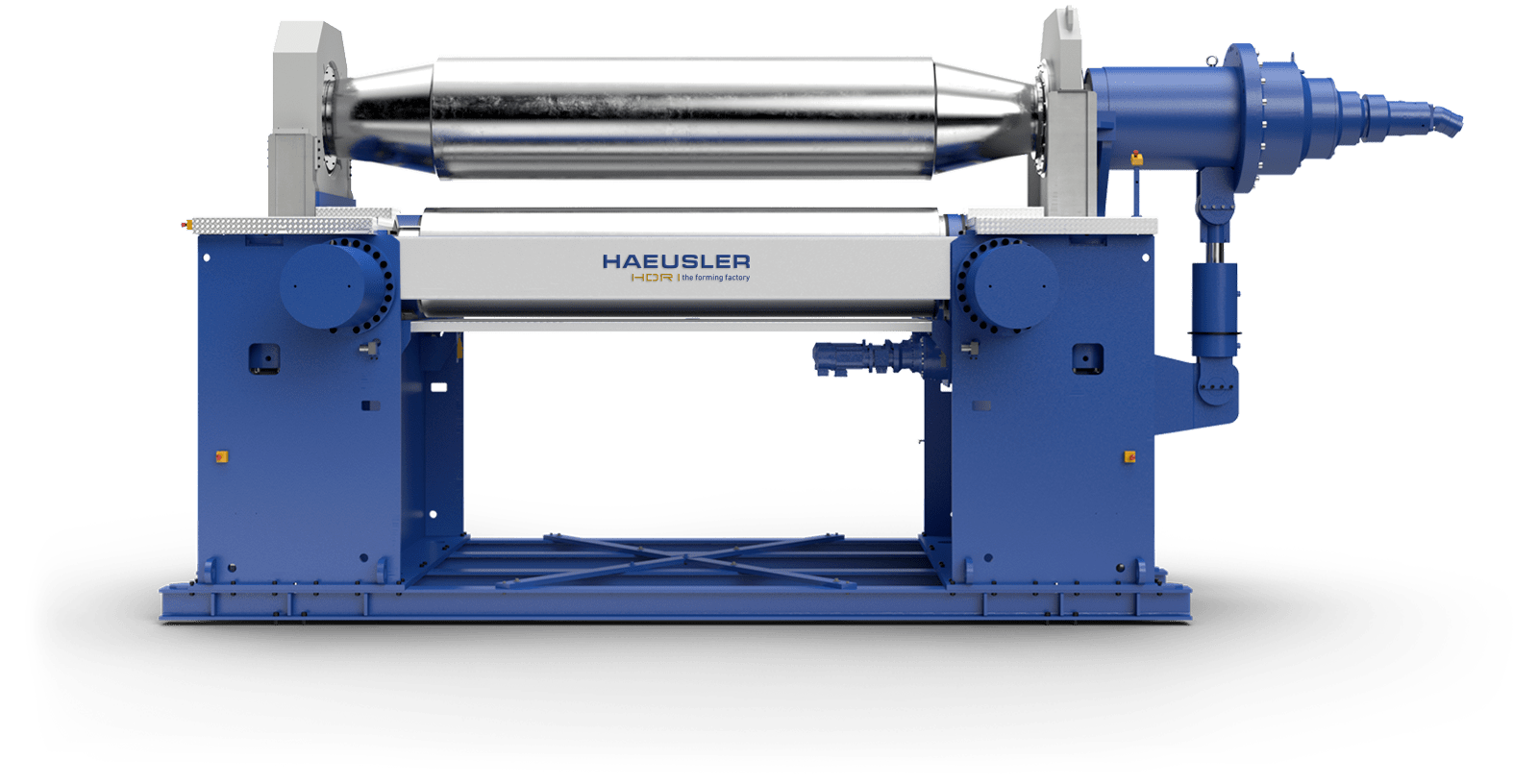

HDR 3-roll plate bending machine

A machine as flexible

as is its variable geometry

First-class HAEUSLER quality and expertise paired with durability and low operating costs – this is exactly what you get with the 3-roll plate bending machine HDR from HAEUSLER. The HDR plate bending machine convinces by the individually adjustable bending geometry of the bottom rolls, which enables rolling of very thick plates as well as small diameters. Best bending results can be achieved thanks to the use of the patented top roll adjustment by using only pressure loaded cylinders and thus resulting machine symmetry.

Advantages

at a glance

Best bending results

Easy maintenance

Highest accuracy

Optimum roll material

Highest torques

Easy to operate

HDR 3-roll plate bending machine │ Machines in Real-Life Operation

Strong performance for

every bending task

Power development

with sensitivity

There a different designs of 3-roll plate bending machines, where the most advanced design is characterized by its variable adjustment of the rolls. Following this variable machine geometry the HAEUSLER HDR allows linear adjustment of the 2 bottom rolls independently from each other, while the top roll can be adjusted vertically. All 3 rolls can be driven, inclined roll setting enables cone bending. This design principle offers, compared to all other 3-roll machines, significant advantages regarding minimization of flat ends, best bending quality and workpiece handling. In addition, the HDR system is the only concept where the bending geometry can be set variably. This means that the deformable wall thicknesses can be adjusted according to the position of the bottom rolls within the performance range of the plate bending machine. The smaller the asymmetry of the bottom rolls to the top roll, the greater the possible wall thicknesses by accepting longer flat ends. The maximum deformable wall thickness is obtained with symmetrical position of the bottom rolls. Due to this functional principle, even the thickest plates can be bent with relatively low forces and thus extremely economically.

Best bending results

Due to the patented infeed of the top roller via four identical cylinders, absolute bending symmetry can be achieved – this is the basis for perfect bending results.

Highest accuracy

By using special T-slides in the drive and folding bearing stand, the guideways could be more than doubled compared to other suppliers. As a result, the highest bending accuracies can be achieved on a permanent basis.

Optimum roller material

HAEUSLER uses only the most suitable roller material for our bending machines. The material is forged at our partner forges as close as possible to the final contour and then finally machined. This ensures that the properties created by the forging process are optimally transferred to the finished roll. For our customers, this means maximised service life.

Highest torques

By using rotary drives with very high torques, we enable our customers to finish their products in just a few work steps and thus increase their productivity. In addition, all rotary drives are equipped with a fast-acting braking system as standard. This ensures precise and safe working.

Easy maintenance

All main cylinders of the machine can be reached in a few simple steps and guarantee easy and quick maintenance.

Easy to use

The menu navigation on the touch display is intuitive, the machine actively supports you during operation. All bending-relevant data can be displayed and adapted on the control.

Specific features

of the HDR 3-roll plate bending machine

The unique design features of the HDR 3-roll round bending machine contribute to the high quality and long service life of the machine. Even the base frame offers maximum stability under the bending forces exerted and consists of a compact, closed design. The rollers of the round bending machine are also manufactured to be extremely stable: The high-alloy and non-surface-hardened steels prevent cracks on the rollers. The rollers are driven by a high-quality 3-roller drive, which enables precise panel handling and high traction.

Additional advantages of the new design

Since the bearings and frame of the new HAEUSLER HDR design are absolutely symmetrical, the plate bending machine ensures high bending quality. In addition, the movements of the top roller are realised by two times two identical cylinders, which in turn are 100 percent symmetrical. This results in high bending accuracy during the bending process. In addition to these aspects, the HDR 3-roll round bending machine has numerous other advantages to offer. This sets it apart from other 3-roll bending machines on the market in many areas.

Advantages compared to other 3-roll bending machines

The HAEUSLER HDR bending machine differs in many ways from other 3-roll bending machines on the market. For example, the symmetrical design of the HDR ensures accurate and optimal bending results. It is difficult to achieve a good bending result on machines with an asymmetrical design. Also, the four used and identical pressure cylinders of the HDR bending machine offer considerable advantages compared to outdated designs of competitors, such as highly accurate synchronisation.

HDR 3-roll round bending machine detailed

These are by no means all the advantages of the HDR 3-roll round bending machine from HAEUSLER: In our white paper you can find out all the details in full. There you will see, among other things, how exactly the HDR differs from other machines on the market as well as the functional principle of the HDR bending machine with the help of clear graphics.

HDR machines in use worldwide

Whether China, Australia or India – HAEUSLER HDR round bending machines are in use all over the world. Get to know the HDR in action with our references.

More details about

the properties of HDR?

Discover the HAEUSLER HDR plate bending machine in detail.

HDR 3-roll plate bending machine │ Case Study: SeAH Wind (England)

CALIBRATION TECHNOLOGY AT THE HIGHEST LEVEL

For the world’s largest wind turbine production

Standard equipment

Automatic central grease lubrication for easy maintenance

By using an automatic central grease lubrication system, all relevant points of the machine are automatically lubricated.

Fast reacting overrun brake for precise bending

The quick-reacting overrun brakes fitted as standard enable the operators to work very precisely. Furthermore, these brakes are an important safety factor, as they prevent plates from slipping out of the machine unintentionally.

Ethernet connection for online access

The online access enables our service engineers to access our customers’ roll bending machine within the shortest possible time and to ensure optimum support.

Optional equipment

Change rolls for bending small diameters

Exchangeable rolls enable our customers to bend even very small diameters. HAEUSLER machines are equipped in such a way that the roll in use is automatically recognized and the operating pressure is regulated accordingly.

Plate stops for plate positioning

The optionally available plate stop simplifies the alignment of the plate in the machine, is time saving and helps to achieve best bending results. Faster rotation for increased productivity

Faster rotation for increased productivity

Especially when bending very large diameters, the speed of rotation of the machine is decisive for productivity. For this reason HAEUSLER machines can be equipped with an increased rotational speed of up to 8m/min.

Optional accessories

Upper support for simplified bending of large diameters

Upper supports simplify the bending of large diameters, as the weft to be bent can be held and supported at 12 o’clock position during the bending process.

Lateral support for simplified bending of large diameters

Side supports can be fitted on both sides of the machine to assist the operator when bending large diameters.

Infeed roller table for quick and easy feeding of the plates into the machine

Infeed roller tables (optionally also with centring device) simplify loading the machine. Sheets are placed on the roller table and transported from there into the round bending machine.

HAEUSLER

Product Overview

Experience the full HAEUSLER world. All products, all services, projects and more.

HDR applications

the universal bending genius.

Due to the variably adjustable bending geometry of the HAEUSLER HDR, the areas of application of the machine are extremely versatile. Thus HDRs are often used in the following industries:

Learn more?

You can find more information about HAEUSLER HDR in our product brochure.

FAQ

Important questions about

the HDR 3-roll round bending machine

The HDR 3-roll plate bending machine from HAEUSLER offers outstanding performance and versatility. In this FAQ, we answer the most important questions about the features, advantages, and maintenance requirements of this machine.

What are the main features of the HDR 3-roll plate bending machine?

The HDR 3-roll plate bending machine features individually adjustable bottom rolls and a vertically adjustable top roll. This allows for flexible adjustment to various bending geometries and precise bending of plates. This 3-roll bending machine is ideal for industrial applications.

What advantages does the HAEUSLER HDR concept offer compared to other 3-roll bending machines?

HAEUSLER HDR 3-roll plate bending machines have a symmetrical design that ensures optimal bending results and high accuracy. The use of four identical hydraulic cylinders allows for precise synchronization and better handling of the plates. This makes the HDR the best choice among 3-roll bending machines.

How does the bending process of the HDR 3-roll plate bending machine work?

The bending process of the HDR 3-roll plate bending machine involves several steps, including raising the rolls, centering the plate, and pre-bending both sides of the plate. This process ensures uniform and precise bending and demonstrates the efficiency of the 3-roll plate bending machine.

How often should the bending machine be maintained?

Regular maintenance of the HDR 3-roll plate bending machine is recommended every six months to ensure optimal performance. This 3-roll bending machine is equipped with easily accessible cylinders and an automatic central lubrication system, making maintenance easier.

Are there training sessions available for operating the machine?

Yes, HAEUSLER offers comprehensive training for the operation and maintenance of the HDR 3-roll plate bending machine to ensure that operators can use the machine efficiently and safely. This is an advantage not all manufacturers of 3-roll bending machines offer.

What material are the rolls of the HDR plate bending machine made of?

The rolls of the HDR 3-roll plate bending machine are made of high-alloy, non-surface-hardened steels to prevent cracks in the rolls and ensure a long service life. This sets them apart from other 3-roll bending machines on the market.

This might also

interest you

3-roll round bending machines

Get to know the complete range of our 3-roll round bending machines.

DISCOVER MORE

Downloads & Media

Download additional material on our products and services.

DISCOVER MORE

HAEUSLER is certified

according to DIN EN ISO 9001.

TO THE CERTIFICATE