FLEX bending machine│A true all-rounder

MORE FLEXIBLE, FASTER,

SAFER

FLEX bending machine│A true all-rounder

ENGINEERED FOR CHALLENGES.

BUILT FOR RESULTS.

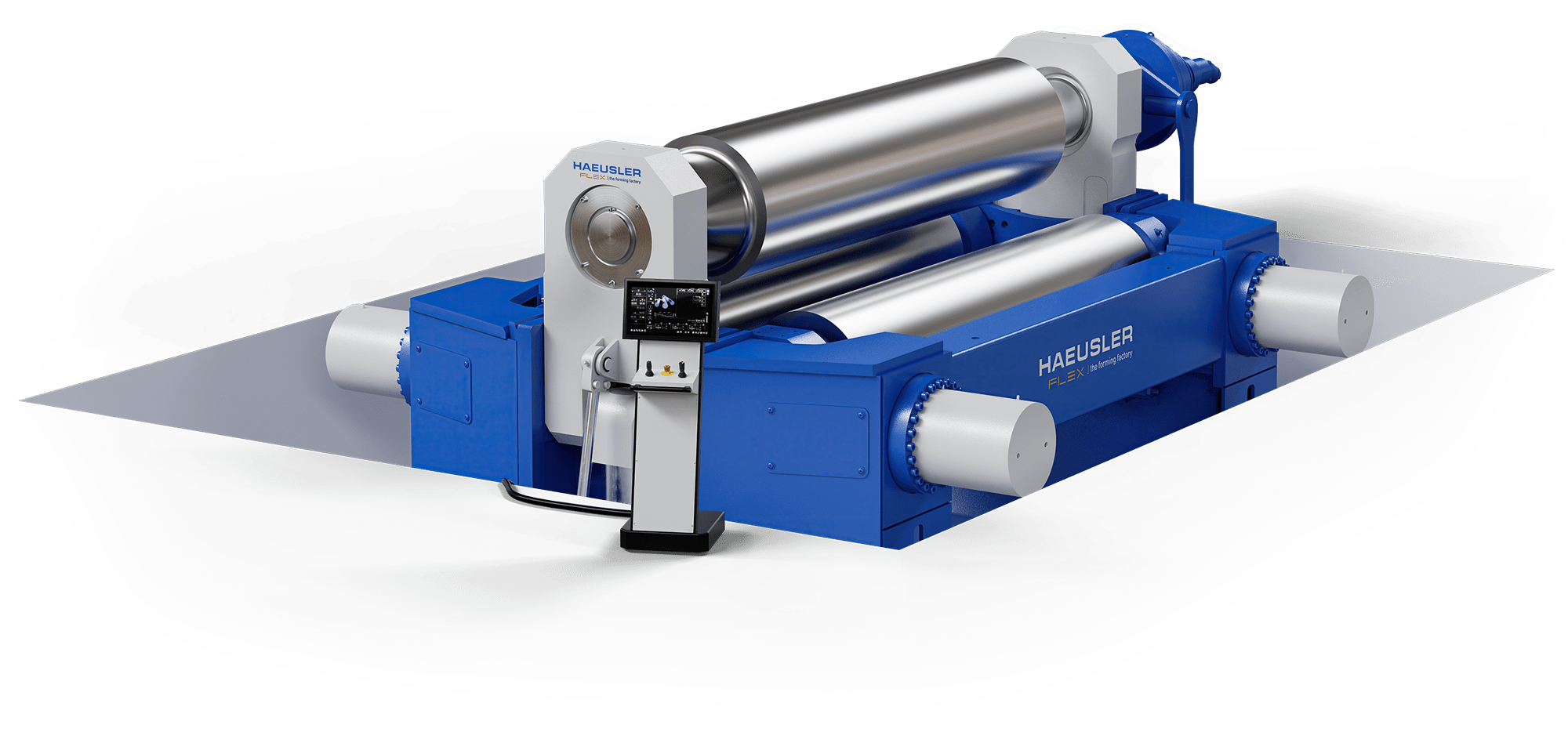

FLEX stands for flexibility, speed, and safety – making it an indispensable tool in a wide range of manufacturing processes. HAEUSLER’s new bending machine forms workpieces in a single pass. A wide variety of components, materials, and geometries can be processed with precision and repeatability – even without years of in-house bending experience! The new Traction Controller® system on the 3-roll bending machine automatically ensures constant clamping of the plate during the entire bending process. This guarantees maximum safety, as it is impossible for the plate to slip. A machine system for those who don’t need a second try.

Advantages

at a glance

Maximum flexibility in processing

High speed in production

Reliable safety in the process

Maximum intelligence in control

A technological edge

that pays off

The FLEX bending machine combines the best of modern bending technology in a single system. A wide variety of geometries, materials, and plate thicknesses can be processed in just one pass – all while meeting the highest safety standards. The intelligent BENDtronic® control system automatically calculates and executes the optimal bending scheme, ensuring precise, reproducible results – even with less experienced operators.

BENDtronic® control

HAEUSLER’s intelligent control system automatically generates the optimal bending scheme and process – enabling precise and repeatable bending without any prior operator experience or specific bending knowledge.

Robust construction

The front and rear columns are made from a single piece. The closed frame structure absorbs all process forces internally – reducing foundation requirements, shortening installation time, and saving space.

Low operating costs

High-quality components, a low-maintenance design, and reduced downtime lower operating costs over the machine’s entire service life. Automatic central lubrication and easy access to key components further simplify maintenance and servicing.

Symmetrical adjustment cylinders

The symmetrical adjustment cylinders ensure smooth operation and reduce the need for adjustments – delivering greater efficiency and operator comfort.

Low-wear roll guidance

Our systems deliver consistently precise results with minimal maintenance requirements. This ensures reliable performance and high availability in daily operation.

FLEXIBILITY

CAN PRODUCE ANYTHING

FLEX adapts to a wide range of requirements: whether thin or thick, simple or complex – the machine bends a variety of geometries and materials automatically at its performance optimum. With the right accessories, it is suitable for virtually any industry. Whether for onshore or offshore wind turbines, silo and machine construction, or tank manufacturing – the FLEX masters the challenges of these industries like no other, and all at competitive prices!

SPEED

BEND IN ONE GO

Thanks to its unique bending technology, a workpiece can be formed in a single pass. You bend on the inlet side, round the weft and finish bending on the outlet side in one go. This saves time, reduces process steps, and significantly increases productivity. The BENDtronic® control system takes care of the entire process and makes bending possible without years of experience!

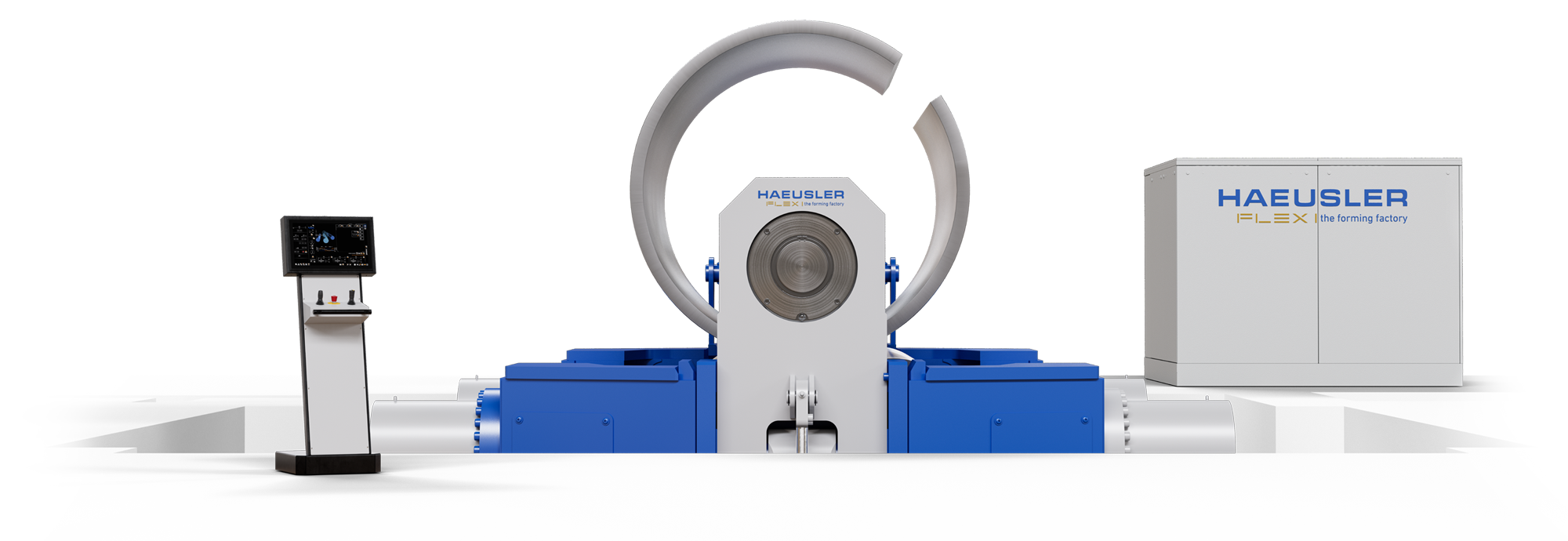

TRACTION CONTROL®

THE PLATE IS CLAMPED CONSTANTLY

The new Traction Controller® system automatically ensures constant clamping of the plate during the entire bending process. This reliably prevents slipping and minimizes the risk of bending errors or accidents – for greater process safety and peace of mind during operation.

PRODUCT RANGE

GEOMETRIES, PLATE THICKNESSES & MATERIAL VARIETY

The FLEX bending machine thinks ahead. Thanks to the innovative BENDtronic® control system, bending is not only precise but also intuitive. The system automatically handles complex calculations – including bending schemes, roll settings, and load distribution. This protects the machine from overload and keeps the process permanently within the optimal performance range. Whether working with changing materials, demanding geometries, or cone bending, BENDtronic® adjusts all parameters via software – for precise and repeatable results without the need for prior experience. Even less trained personnel can achieve reproducible, top-quality results.

DISCOVER MORE

MACHINE RANGE

FLEX IS SELECTION

The following sizes are available as standard with short delivery time.

| 1100 Series | FLEX 3000-1100FLEX 3000-1100 | FLEX 4000-1100 |

|---|---|---|

| Rolls width (mminches) | 3000122 | 4000159 |

| Rounding capacity (mminches) | 1023 3/4 | 893 3/8 |

| Pre-bending capacity (mminches) | 783 | 632 5/8 |

| 1400 Series | FLEX 3000-1400FLEX 3000-1400 | FLEX 4000-1400 |

|---|---|---|

| Rolls width (mminches) | 3000122 | 4000159 |

| Rounding capacity (mminches) | 1225 1/4 | 1064 3/4 |

| Pre-bending capacity (mminches) | 934 1/4 | 763 7/8 |

| 1700 Series | FLEX 3000-1700FLEX 3000-1700 | FLEX 4000-1700 |

|---|---|---|

| Rolls width (mminches) | 3000122 | 4000159 |

| Rounding capacity (mminches) | 1414 1/2 | 1234 |

| Pre-bending capacity (mminches) | 1303 5/8 | 1073 1/4 |

| 2100 Series | FLEX 3000-2100FLEX 3000-2100 | FLEX 4000-2100 |

|---|---|---|

| Rolls width (mminches) | 3000122 | 4000159 |

| Rounding capacity (mminches) | 1554 1/2 | 1354 |

| Pre-bending capacity (mminches) | 1303 5/8 | 1073 1/4 |

| 2600 Series | FLEX 3000-2600FLEX 3000-2600 | FLEX 4000-2600 |

|---|---|---|

| Rolls width (mminches) | 3000122 | 4000159 |

| Rounding capacity (mminches) | 1785 7/8 | 1565 1/4 |

| Pre-bending capacity (mminches) | 1554 3/4 | 1274 1/4 |

| 3300 Series | FLEX 3000-3300FLEX 3000-3300 | FLEX 3000-3300 |

|---|---|---|

| Rolls width (mminches) | 3000122 | 4000159 |

| Rounding capacity (mminches) | 2056 1/2 | 1805 5/8 |

| Pre-bending capacity (mminches) | 1865 1/4 | 1544 5/8 |

Standard

equipment

Automatic central grease lubrication

Thanks to the integrated central lubrication system, the FLEX automatically supplies all relevant lubrication points with grease – reducing downtime and increasing efficiency in daily operation.

Fast-responding brake for precise bending

The standard integrated brake reacts instantly and prevents unwanted slipping of plates. This not only increases accuracy but also enhances safety during bending.

Ethernet connection for online access

Via the Ethernet connection, our service engineers can access the FLEX in no time – providing fast assistance and optimal support for questions or adjustments.

Optional

equipment

Interchangeable rolls for bending small diameters

Thanks to its interchangeable rolls, the FLEX can be easily configured for very small diameters. The machine automatically detects which roll is installed – including pressure adjustment.

Plate stop for plate positioning

The optional plate stop makes it easier to position plates accurately on the FLEX, ensuring precise results and saving time in the setup process.

Increased rotation speed for greater productivity

For particularly large components, the FLEX can optionally be equipped with a higher rotation speed – ideal for maximum throughput in series production.

Optional

accessories

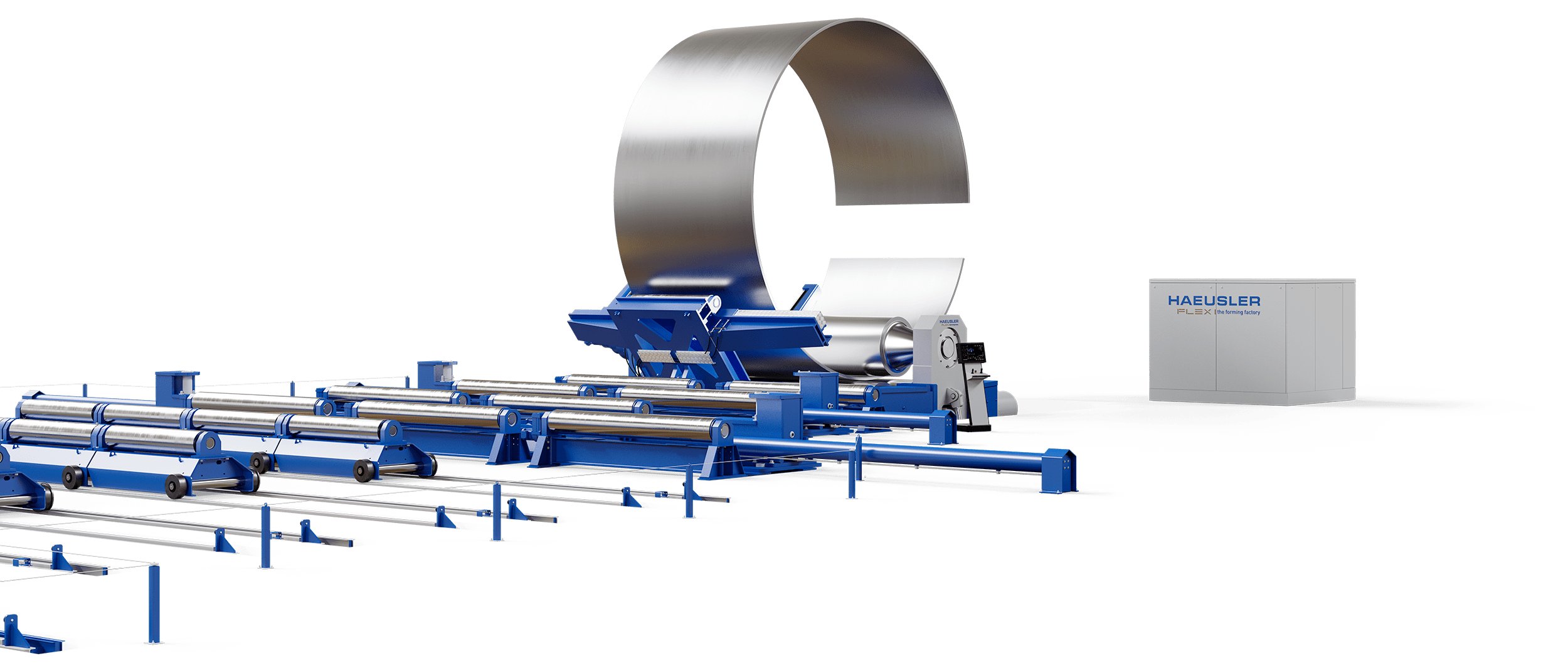

Upper Support for large diameters

The upper support helps keep the plate precisely in position during the bending process – for perfect curves with large diameters.

Side support for large diameters

Double-sided mountable side supports provide additional stability when bending large plates and make handling easier for the operators.

Entry roller table with centering device

The entry roller table (also available with centering device) makes feeding the plates especially convenient. The plates are guided ergonomically and directly into the machine.

The applications of

the FLEX bending machine

Whether cylindrical, conical or complex – FLEX is used wherever maximum precision and process reliability are required. Discover some example applications.

Know more. Bend better.

Download the brochure now and discover all the details, advantages, and technical highlights of the HAEUSLER FLEX bending machine.

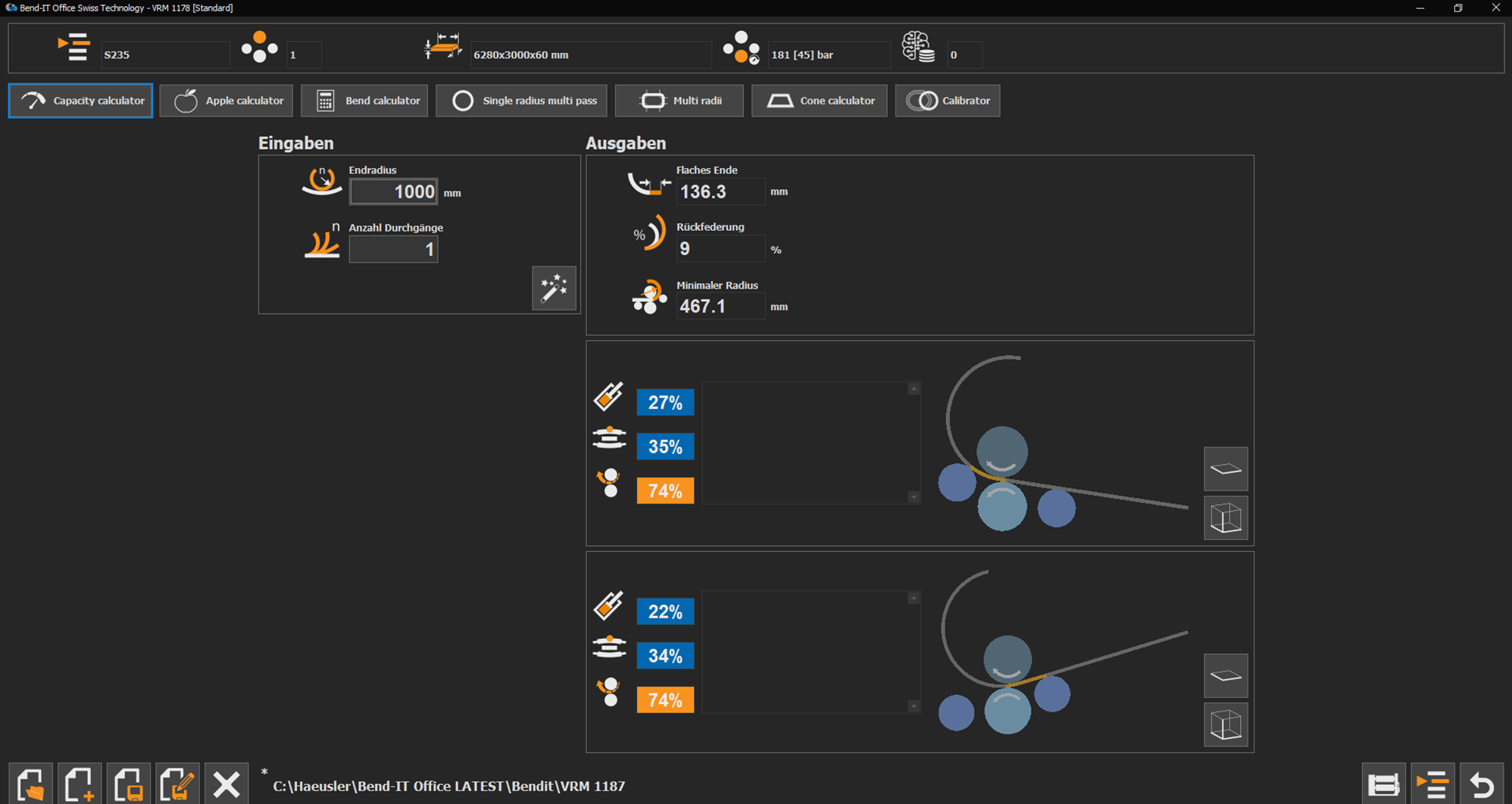

BENDIT SIMULATOR

DISCOVER THE LIMITS OF PLATE BENDING ONLINE !

With the BENDIT Simulator, you can realistically simulate bending processes – for reliable calculations and optimized production planning. Discover it now.

DISCOVER MORE