Retrofit

We modernise

your machines

Retrofit

Modernise now and avoid downtime

Why upgrade to the new control unit?

Why upgrade to the new control unitThe old Meier control unit has been officially discontinued. The spare parts for the control unit and the associated fibre optic components are no longer available and repairs are no longer possible. In addition, remote access to the control system can no longer be realised. To ensure a reliable and future-proof solution, we recommend switching to the latest control technology. This electrical conversion modernises your machines and production processes.

What does our retrofit offer ?

Thanks to our many years of experience, we offer fast and uncomplicated solutions for your requirements. The new, innovative control system from HAEUSLER sets standards in efficiency and performance. Thanks to professional remote access, we enable precise troubleshooting and fast problem solving. We also ensure the long-term availability of spare parts to keep your machines modernised and running smoothly at all times.

| Current status after the conversion | VRM NEO 4050-680 | |

|---|---|---|

| Control System | PC and PLC as separate hardware, each with its own software | Beckhoff 21’ touch panel and control cabinet PC with integrated soft PLC - faster communication |

| BUS-System | Fibre optic and Profi Bus combined | EtherCAT- faster cycle times- only one bus system for everything |

| Software | Windows interface with text fields and digital display or manufacturer-specific special software without customisation options | Graphical user interface specially adapted with real-time simulation and speedometer display - customisable - clearer / more user-friendly |

| Support | Spare parts no longer available due to the supplier going out of business. Support difficult as there are only a few technicians left. | Spare parts in stock- Fast online support through remote access- Software is developed in-house, therefore short distances for problem solving |

| Position transmitter | Incremental encoder | Absolute encoder with EtherCAT- no more reference run necessary- faster communication |

| Security | The modules installed are no longer state of the art | New modules with two-channel technology |

Assembly on site

Additional services

REPAIR

& REPLACEMENT OF MEASURING SYSTEMS

We exchange and replace all measuring systems without any complications.

SERVICE REQUESTS

REPAIR

& REPLACEMENT of electrical parts

We exchange and replace electrical parts with ease.

SERVICE REQUESTS

Instruction & training of personnel

We train your staff on site on the new control system and standards.

SERVICE REQUESTS

Commissioning & assembly on site

We accompany and carry out the commissioning. This guarantees a smooth start to production.

SERVICE REQUESTS

Electrical conversion

Completely installed switch cabinet

- Industrial PC and UPS

- Individually adjustable climate control

- Main switch

- Busbar distribution

- Fuses and motor control

- 24 V supply and fuses

- Emergency stop control

- Beckhoff Ether CAT modules as input and output interface

- VPN router for remote access (internet access required)

- Fully assembled and wired

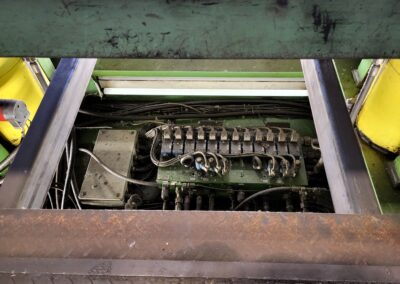

Hydraulic conversion

Revision for your machine components

- Replacement of the mechanical synchronisation with control valves

- Installation of compact, state-of-the-art valve blocks

- The new blocks are supplied fully equipped and thus considerably reduce the

- installation work on site.

- Replacement of old valves with current models

- Replacement of old pipes and hoses

- New seal and disc sets for all rotary brakes to ensure safety

INNOVATION

BENDtronic® control system

BENDING BECOMES CHILD’S PLAY

The revolutionary BENDtronic® from HAEUSLER allows anyone to control not only the movements of the machine, but also the bending result itself. The software is graphically supported and enables bending in one or more passes. The BENDtronic® contains various auxiliary tools that optimally support the operator during bending.

Capacity Calculator

Feasibility check of the tasks. In addition, the machine utilisation, the remaining straight ends and the expected springback are calculated.

Bend Calculator

Calculates the required positions of the rollers to achieve the desired radius.

Cone Calculator

Supports the operator when bending cones. The software calculates the feasibility and the settings required to bend an individual cone.

Apple Calculator

Calculation of various options to achieve the desired apple shape of a cylindrical part during bending.

Tim wagner

Mechanic / Project Manager HAEUSLER

A permanent fixture at HAEUSLER for 12 years. He knows all about retrofitting and overhauls and has extensive experience as an on-site fitter and project manager.

« Short report from long experience »

Retrofit applications are exciting because existing machines are modernised, thereby extending their service life. It’s fascinating to see how new technologies and control systems can bring old machines back up to date. Replacing and modernising the control system and installing new sensors and measurement technology, as well as replacing hydraulic or pneumatic components, are my most frequent tasks. Co-ordinating old mechanical parts with modern control systems is often tricky. Retrofit projects have to be carried out quickly because the machine is needed for production.

Feedback from retrofit customers

Modernisation is appreciated!

This might also interest you

Downloads & Media

Laden Sie zusätzliches Material über unsere Produkte und Dienstleistungen herunter.

DISCOVER MORE

3-roll plate bending machine

Our 3-roll bending machines offer the widest range of applications.

DISCOVER MORE

4-roll plate bending machines

With the 4-roll bending machines from HAEUSLER bending becomes child’s play.

DISCOVER MORE